27

2023

-

04

The difference between non-woven fabric and melt blown fabric

Non woven fabrics and melt blown fabrics are both textile fabrics, but their processing and manufacturing processes are different.

Non woven fabrics and melt blown fabrics are both textile fabrics, but their processing and manufacturing processes are different. In addition, there are also some differences in performance between the two fabrics. Compared to melt blown fabrics, non-woven fabrics have different applicability and the main raw materials used for processing the two are also different. Now, let's take a closer look at both of these in detail.

1. Different raw materials. Non woven fabrics mainly use polypropylene particles as the raw material for melt blown fabrics, while melt blown fabrics mainly use polypropylene as the raw material.

2. Different functions. The former is moisture-proof, breathable, flexible, lightweight, non combustible, easy to decompose, non-toxic, non irritating, and recyclable; Melt blown fabric has many gaps, a fluffy structure, good wrinkle resistance, and good filtration performance.

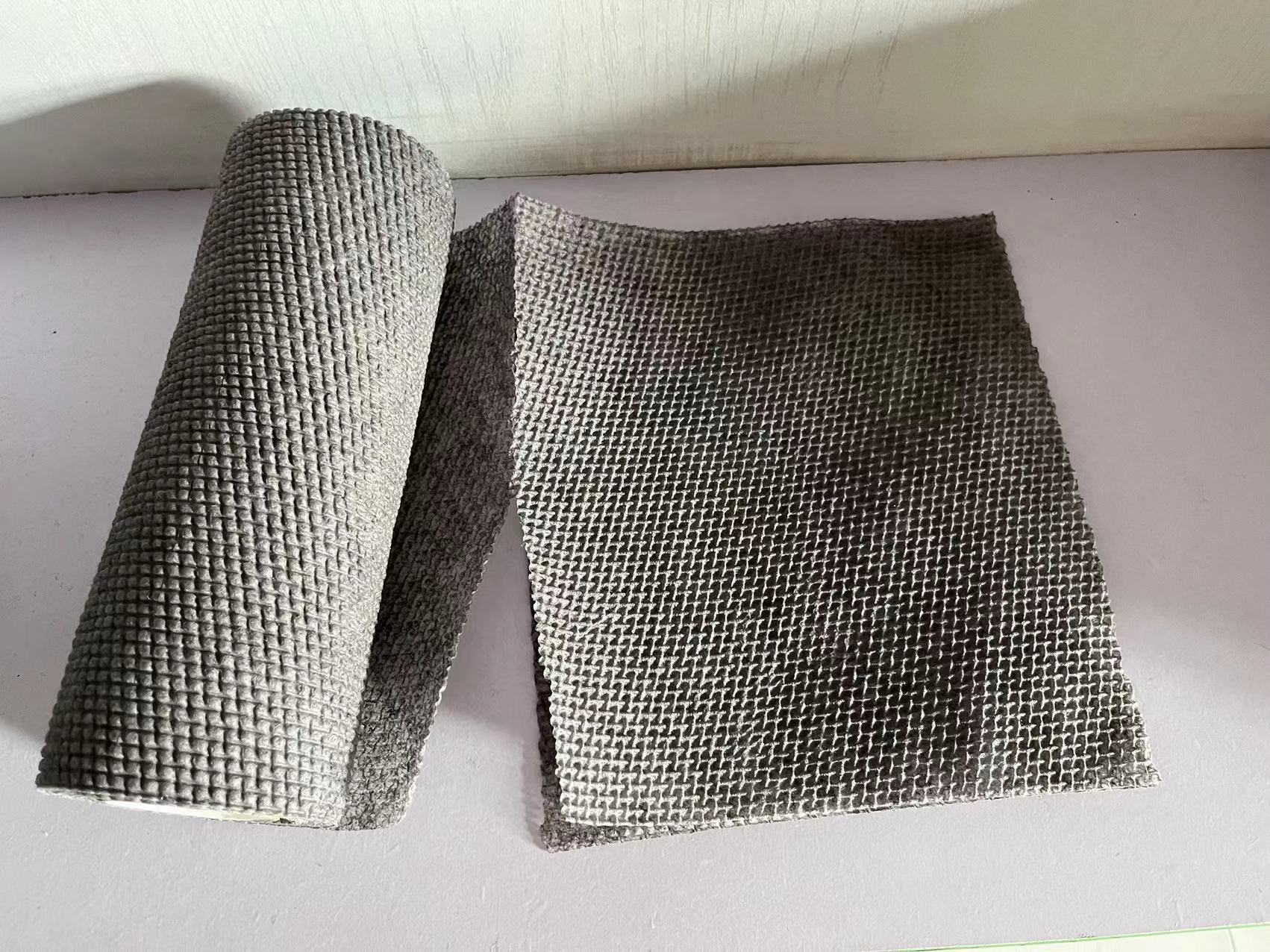

3. Different uses. Non woven fabric without warp and weft threads, easy to cut and sew, lightweight and easy to shape, deeply loved by handicraft enthusiasts.

Non woven fabric is a type of fabric that does not require weaving. It only needs to orient the randomly arranged textile short fibers to form a network structure, and then strengthen them through mechanical, thermal bonding, or chemical methods. Fibers are not woven one by one, but are directly bonded together through physical methods. It breaks the traditional textile principle of non-woven fabrics and has the advantages of short process, fast production speed, high output, and low cost.

Melt blown fabric is mainly made of polypropylene, with a fiber diameter of 1-5 microns. Melt blown cloth has many gaps in its structure, which is fluffy and wrinkle resistant, so it has good filtration, shielding, insulation, and oil absorption properties. It can be used for gas-liquid filtration, isolation, absorption, masks, insulation, oil absorbing materials, wiping cloths, and many other fields.

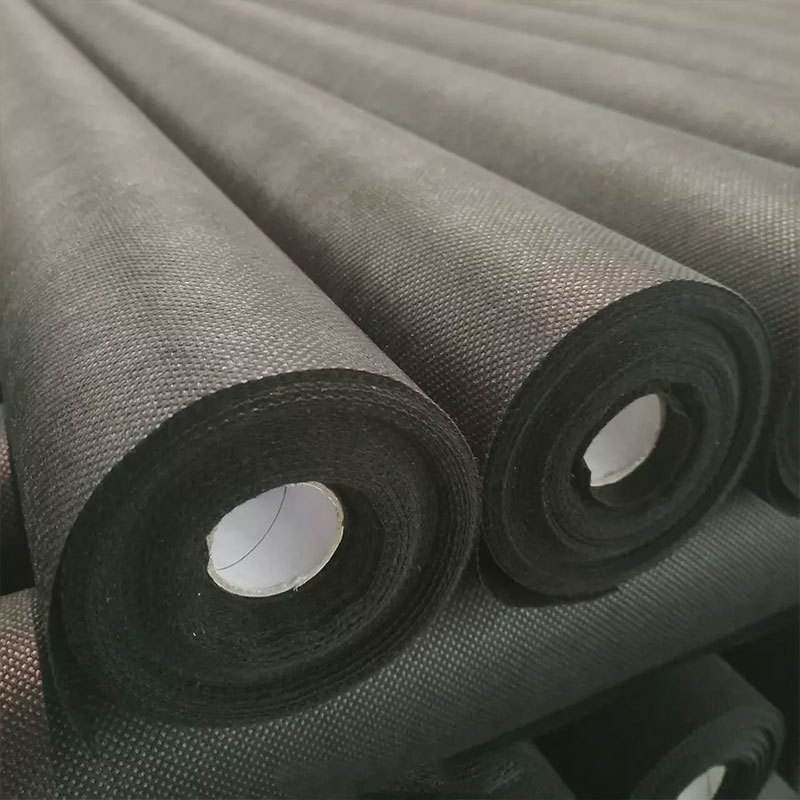

Using non-woven polypropylene resin as the main raw material, the specific gravity is only 0.9, which is only 3/5 of cotton. It is fluffy and has a good feel. It is composed of fine fibers (2-3D), formed by the fusion of light points. The finished product has moderate softness and a good feel. Polypropylene chips do not absorb water, have zero water content, and the finished product has good water repellency. Made of 100% fiber, it has good breathability and the surface of the fabric is easy to maintain dryness and cleanliness.

Non woven fabrics can use the advantages of small pores to purify air, block bacteria and viruses, and are non-toxic and non irritating. The product is made of raw materials that comply with FDA standards and do not contain other chemical components. Its performance is stable, non-toxic, odorless, and non irritating to the skin. Polypropylene is a chemically inert substance that is not eaten by insects and can isolate bacteria and insect attack in liquids; Antibacterial, alkali resistant, and the strength of the finished product is not affected by corrosion.

In summary, compared to melt blown fabrics, non-woven fabrics have faster production speed, higher output, and a wider range of applications. In addition to distinguishing from melt blown fabrics in the above aspects, it can also be distinguished in terms of breathability and tensile strength.