25

2025

-

04

Why Polyester Spunbond Fabric is the Future of Non-Woven Materials

Why Polyester Spunbond Fabric is the Future of Non-Woven Materials The textile industry is evolving rapidly, and among the innovative materials making waves is polyester spunbond fabric. As a subtype of non-woven fabric, polyester spunbond offers numerous advantages that position it as the leading choice for various applications. In this article, we delve deep into the characteristics, benefits,

Why Polyester Spunbond Fabric is the Future of Non-Woven Materials

The textile industry is evolving rapidly, and among the innovative materials making waves is polyester spunbond fabric. As a subtype of non-woven fabric, polyester spunbond offers numerous advantages that position it as the leading choice for various applications. In this article, we delve deep into the characteristics, benefits, and future prospects of polyester spunbond fabric, ensuring you understand why it stands out in the crowded landscape of non-woven materials.

Table of Contents

- 1. Introduction to Polyester Spunbond Fabric

- 2. What is Spunbond Fabric?

- 3. Advantages of Polyester Spunbond Fabric

- 4. Applications of Polyester Spunbond Fabric

- 5. Environmental Impact of Polyester Spunbond

- 6. Comparison with Other Non-Woven Materials

- 7. The Future of Polyester Spunbond Fabric

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Polyester Spunbond Fabric

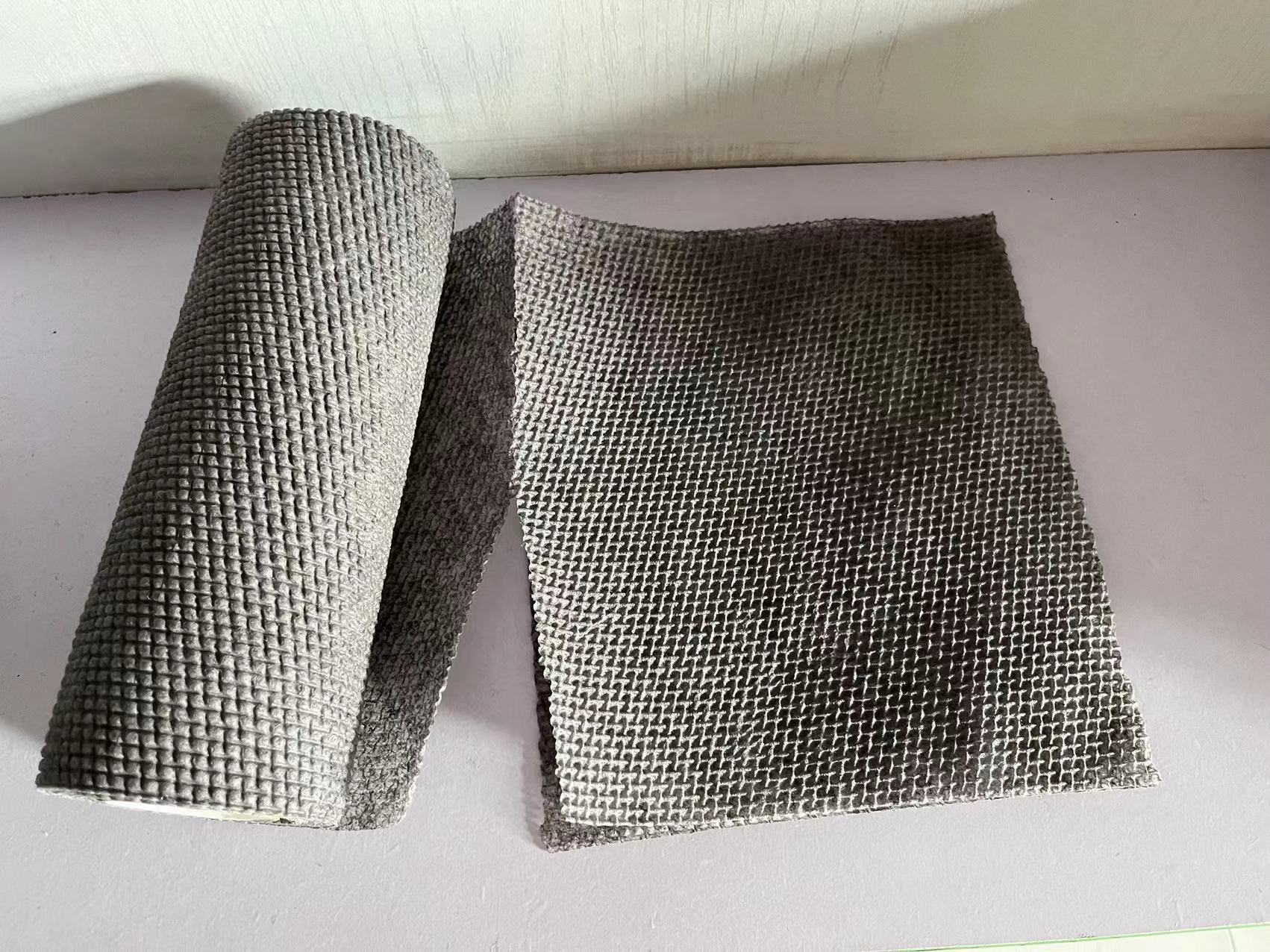

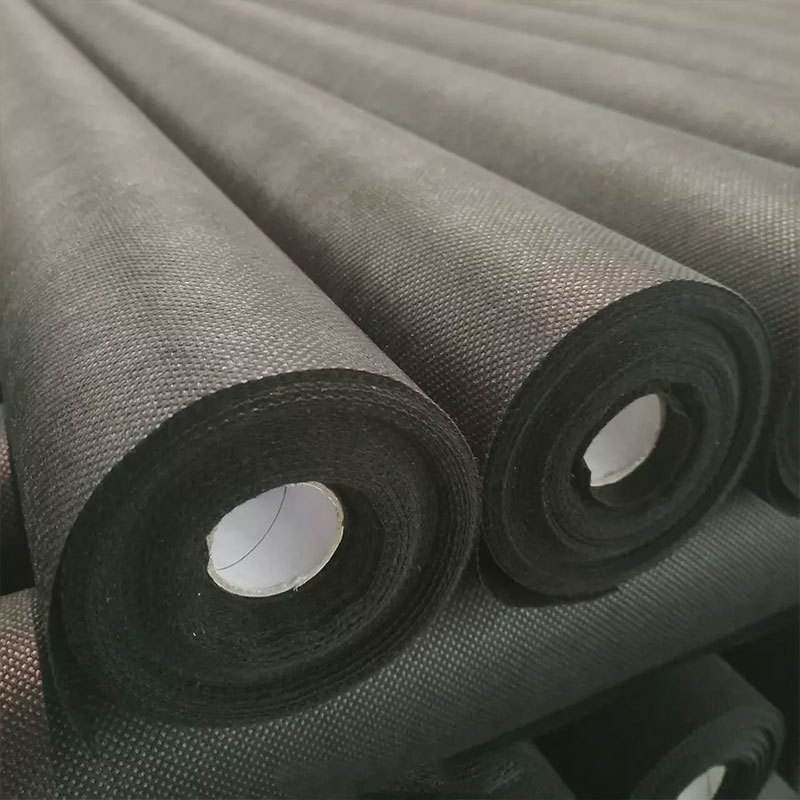

Polyester spunbond fabric, characterized by its unique manufacturing process and fiber structure, is at the forefront of non-woven textiles. Unlike traditional woven fabrics, spunbond is created from continuous filaments, offering exceptional strength and durability. As industries shift towards more sustainable and versatile materials, polyester spunbond emerges as a frontrunner, effectively meeting consumer demands and environmental standards.

2. What is Spunbond Fabric?

Spunbond fabric is produced using a process that involves the continuous extrusion of polymer filaments, which are then laid down in a web-like formation. This method creates a fabric that is both lightweight and robust. The fibers are bonded together through thermal, chemical, or mechanical means, resulting in a non-woven material with excellent properties. The versatility of spunbond fabric allows it to be used in various sectors, from medical to automotive industries.

2.1 The Manufacturing Process of Spunbond Fabric

The manufacturing process of polyester spunbond fabric involves several key steps: polymer extrusion, fiber formation, web formation, and bonding. First, polyester is melted and extruded through a spinneret, producing continuous filaments. These filaments are then cooled and conveyed onto a moving belt, where they are arranged into a web. Finally, the bonded fabric undergoes finishing processes to enhance its properties, making it suitable for diverse applications.

3. Advantages of Polyester Spunbond Fabric

Polyester spunbond fabric boasts a multitude of advantages that contribute to its growing popularity across various industries. Some of the notable benefits include:

3.1 Durability and Strength

One of the standout features of polyester spunbond is its incredible durability. The continuous filament structure provides superior tensile strength, making it resistant to tearing and damage. This durability ensures that products made from this fabric have a longer lifespan, ultimately reducing waste.

3.2 Lightweight and Breathable

Despite its strength, polyester spunbond fabric is lightweight and breathable. This combination makes it ideal for applications such as protective clothing, where comfort and mobility are paramount. The breathable nature of the fabric also allows for moisture management, keeping the wearer cool and dry.

3.3 Cost-Effectiveness

Polyester spunbond fabric is not only high in quality but also cost-effective. The efficient manufacturing process enables mass production at lower costs compared to other textiles. This affordability makes it a popular choice for manufacturers looking to optimize their supply chain without compromising quality.

3.4 Environmental Sustainability

As sustainability becomes a focal point in the textile industry, polyester spunbond fabric stands out due to its recyclable nature. Many manufacturers are now producing spunbond fabrics from recycled polyester, contributing to reduced environmental impact and promoting a circular economy.

4. Applications of Polyester Spunbond Fabric

The versatility of polyester spunbond fabric allows it to be utilized in various sectors, including:

4.1 Medical and Healthcare

In the medical industry, polyester spunbond is widely used for making surgical gowns, drapes, and masks. Its barrier properties, combined with breathability, make it an ideal material for protective gear, ensuring safety for healthcare professionals and patients alike.

4.2 Agriculture

Polyester spunbond fabric is commonly used in agriculture for applications such as crop covers, weed control fabrics, and shading materials. The durability and lightweight properties allow for easy installation and effective protection of crops against harsh weather conditions.

4.3 Home Textiles

In the realm of home textiles, polyester spunbond is utilized in products such as furniture upholstery, curtains, and bedding. Its aesthetic appeal, combined with durability, makes it an attractive choice for interior designers.

4.4 Industrial Uses

Industries such as automotive and construction utilize polyester spunbond for insulation, soundproofing, and filtration applications. The fabric's robustness ensures it can withstand various environmental conditions, making it an essential component in these fields.

5. Environmental Impact of Polyester Spunbond

As environmental concerns rise, it is crucial to evaluate the sustainability of materials used in production. Polyester spunbond fabric presents a favorable profile in this regard:

5.1 Recyclability and Waste Reduction

Polyester spunbond can be recycled into new products, minimizing waste and promoting a circular economy. Many manufacturers are investing in recycling technologies to ensure that discarded spunbond fabrics can be repurposed, further reducing their ecological footprint.

5.2 Reduction of Carbon Footprint

The production of polyester spunbond fabric has a lower carbon footprint compared to traditional woven textiles. Manufacturers are continuously developing eco-friendly processes that further decrease energy consumption and emissions, contributing to a more sustainable textile industry.

6. Comparison with Other Non-Woven Materials

When comparing polyester spunbond fabric with other non-woven materials, it becomes evident why it is the preferred choice in many applications:

6.1 Versatility

While other non-woven fabrics may focus on specific applications, polyester spunbond's versatility allows for use in a wide range of industries. Its adaptability makes it suitable for everything from medical products to home textiles.

6.2 Cost Efficiency

In terms of cost, polyester spunbond offers significant savings without sacrificing quality. Other non-woven fabrics may be more specialized and thus more expensive, whereas polyester spunbond provides a balance of affordability and performance.

7. The Future of Polyester Spunbond Fabric

The future of polyester spunbond fabric is promising, driven by trends in sustainability, innovation, and technology. As consumer preferences shift towards eco-friendly products, polyester spunbond is well-positioned to meet these demands.

7.1 Innovations in Production Processes

Advancements in production technologies are leading to more efficient manufacturing processes, enabling the creation of high-quality polyester spunbond fabrics at lower costs. These innovations will likely further cement polyester spunbond's position in the textile market.

7.2 Increased Demand in Sustainable Products

With consumers increasingly prioritizing sustainable options, the demand for recycled polyester spunbond fabric is expected to rise. Companies that invest in sustainable practices will likely thrive as they cater to environmentally conscious consumers.

8. Frequently Asked Questions

8.1 What are the key properties of polyester spunbond fabric?

Polyester spunbond fabric is known for its durability, lightweight nature, breathability, and cost-effectiveness. It’s also recyclable, making it a sustainable choice in textiles.

8.2 How is polyester spunbond fabric made?

The fabric is produced by extruding polyester filaments, which are then laid down and bonded together using thermal, mechanical, or chemical methods.

8.3 What are the main applications of polyester spunbond?

Main applications include medical and healthcare products, agricultural covers, home textiles, and various industrial uses.

8.4 Is polyester spunbond environmentally friendly?

Yes, especially when produced from recycled materials. It is also recyclable, contributing to waste reduction and sustainability.

8.5 How does polyester spunbond compare to other non-woven fabrics?

Polyester spunbond is more versatile and cost-effective compared to many other non-woven fabrics, making it suitable for a broader range of applications.

9. Conclusion

The future of non-woven materials is bright, with polyester spunbond fabric leading the charge. Its unique properties, coupled with a commitment to sustainability, make it an ideal choice across various industries. As we move forward, embracing innovations and prioritizing eco-friendly practices will ensure that polyester spunbond remains a cornerstone of the textile industry, meeting the demands of both consumers and the environment. With its versatility and cost-effectiveness, we can confidently say that polyester spunbond fabric is truly the future of non-woven materials.

polyester spunbond fabric