20

2025

-

06

Understanding Spunbond Polypropylene Fabric: Key Insights for Professionals in the Nonwoven Textile Industry

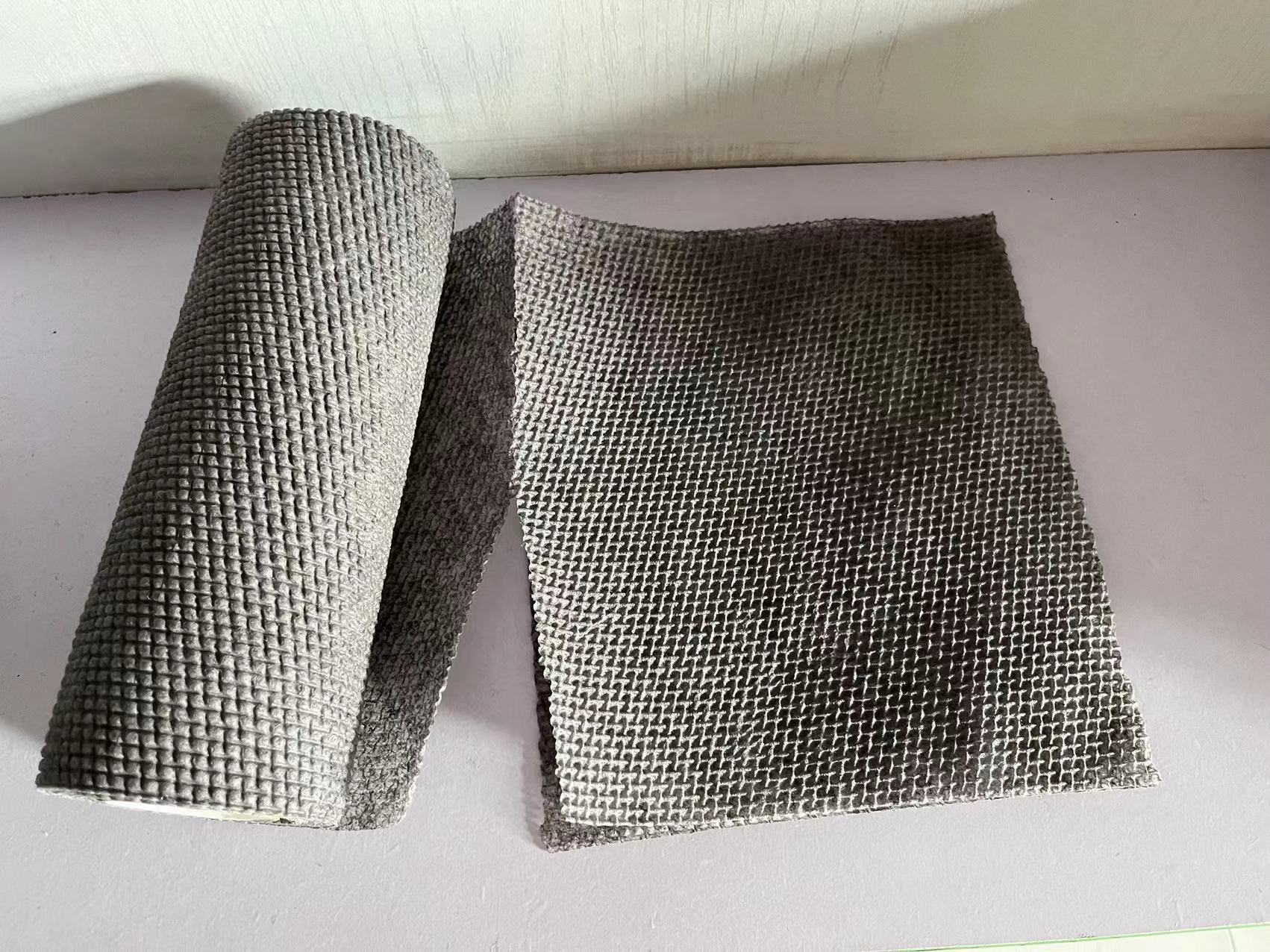

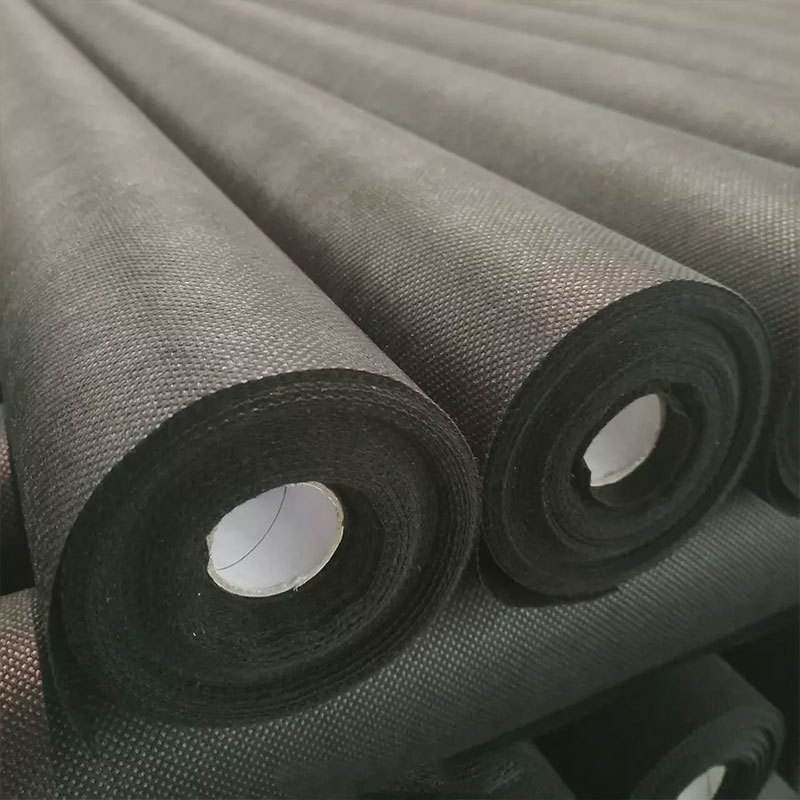

Spunbond polypropylene fabric is a robust, lightweight, and versatile material widely used in the nonwoven textile industry. Composed of thermoplastic polymers, particularly polypropylene, this fabric is produced through a unique process that involves the extrusion and bonding of fibers. The result is a durable fabric that is not only cost-effective but also possesses excellent physical and chemic

Spunbond polypropylene fabric is a robust, lightweight, and versatile material widely used in the nonwoven textile industry. Composed of thermoplastic polymers, particularly polypropylene, this fabric is produced through a unique process that involves the extrusion and bonding of fibers. The result is a durable fabric that is not only cost-effective but also possesses excellent physical and chemical properties, making it suitable for a multitude of applications.

One of the standout features of spunbond polypropylene fabric is its high strength-to-weight ratio. This characteristic allows manufacturers to create products that are both lightweight and incredibly durable. In applications such as geotextiles, agricultural covers, and medical gowns, the strength of spunbond polypropylene ensures that products can withstand demanding conditions while maintaining their integrity.

Moreover, this fabric is known for its excellent breathability and moisture resistance. These properties make spunbond polypropylene an ideal choice for products that require air and moisture permeability, such as disposable hygiene products and filtration materials. Professionals in the textile industry should recognize the importance of these characteristics, especially when designing items for specific end-use applications.

In addition to its functional benefits, spunbond polypropylene fabric is also valued for its environmental sustainability. The production process generates minimal waste, and the fabric itself is recyclable, making it a more eco-friendly option compared to traditional woven textiles. This is an increasingly important consideration for businesses aiming to meet sustainability goals and cater to environmentally conscious consumers.

When it comes to processing and manufacturing, spunbond polypropylene fabric can be easily dyed, printed, and treated to enhance its performance characteristics. Professionals should explore various finishing techniques to optimize the fabric for specific applications, such as adding UV resistance or antimicrobial properties.

As the demand for versatile and sustainable materials continues to rise, spunbond polypropylene fabric stands out as a suitable choice for a wide range of industries, including agriculture, healthcare, and home textiles. Understanding its properties and potential applications will empower professionals in the nonwoven textile industry to innovate and expand their product offerings effectively.

In conclusion, spunbond polypropylene fabric is a multifaceted material that offers numerous advantages for textile professionals. Its unique properties, sustainability, and ease of processing make it an essential fabric in the nonwoven sector. By staying informed about its applications and benefits, industry professionals can make strategic decisions that enhance product performance and meet market demands.

One of the standout features of spunbond polypropylene fabric is its high strength-to-weight ratio. This characteristic allows manufacturers to create products that are both lightweight and incredibly durable. In applications such as geotextiles, agricultural covers, and medical gowns, the strength of spunbond polypropylene ensures that products can withstand demanding conditions while maintaining their integrity.

Moreover, this fabric is known for its excellent breathability and moisture resistance. These properties make spunbond polypropylene an ideal choice for products that require air and moisture permeability, such as disposable hygiene products and filtration materials. Professionals in the textile industry should recognize the importance of these characteristics, especially when designing items for specific end-use applications.

In addition to its functional benefits, spunbond polypropylene fabric is also valued for its environmental sustainability. The production process generates minimal waste, and the fabric itself is recyclable, making it a more eco-friendly option compared to traditional woven textiles. This is an increasingly important consideration for businesses aiming to meet sustainability goals and cater to environmentally conscious consumers.

When it comes to processing and manufacturing, spunbond polypropylene fabric can be easily dyed, printed, and treated to enhance its performance characteristics. Professionals should explore various finishing techniques to optimize the fabric for specific applications, such as adding UV resistance or antimicrobial properties.

As the demand for versatile and sustainable materials continues to rise, spunbond polypropylene fabric stands out as a suitable choice for a wide range of industries, including agriculture, healthcare, and home textiles. Understanding its properties and potential applications will empower professionals in the nonwoven textile industry to innovate and expand their product offerings effectively.

In conclusion, spunbond polypropylene fabric is a multifaceted material that offers numerous advantages for textile professionals. Its unique properties, sustainability, and ease of processing make it an essential fabric in the nonwoven sector. By staying informed about its applications and benefits, industry professionals can make strategic decisions that enhance product performance and meet market demands.

spunbond polypropylene fabric

Prev