23

2025

-

06

The Comprehensive Guide to the Benefits of Utilizing PP Nonwoven Fabric in Your Projects

The Comprehensive Guide to the Benefits of Utilizing PP Nonwoven Fabric in Your Projects Table of Contents Introduction to PP Nonwoven Fabric What is PP Nonwoven Fabric? Advantages of Using PP Nonwoven Fabric 1. Sustainability and Environmental Impact 2. Cost-Effectiveness 3. Durability and Strength 4. Versatility in Application

The Comprehensive Guide to the Benefits of Utilizing PP Nonwoven Fabric in Your Projects

Table of Contents

- Introduction to PP Nonwoven Fabric

- What is PP Nonwoven Fabric?

- Advantages of Using PP Nonwoven Fabric

- 1. Sustainability and Environmental Impact

- 2. Cost-Effectiveness

- 3. Durability and Strength

- 4. Versatility in Applications

- 5. Breathability and Comfort

- Applications of PP Nonwoven Fabric

- How to Select the Right PP Nonwoven Fabric

- The Future of PP Nonwoven Fabric

- Conclusion

- FAQs about PP Nonwoven Fabric

Introduction to PP Nonwoven Fabric

PP nonwoven fabric, made from polypropylene, is a revolutionary material that has transformed various industries due to its unique properties and versatile applications. As the demand for innovative, sustainable solutions increases, understanding the benefits of utilizing PP nonwoven fabric becomes essential for manufacturers and consumers alike. This article delves into the numerous advantages of PP nonwoven fabric, its applications, selection criteria, and future potential in the marketplace.

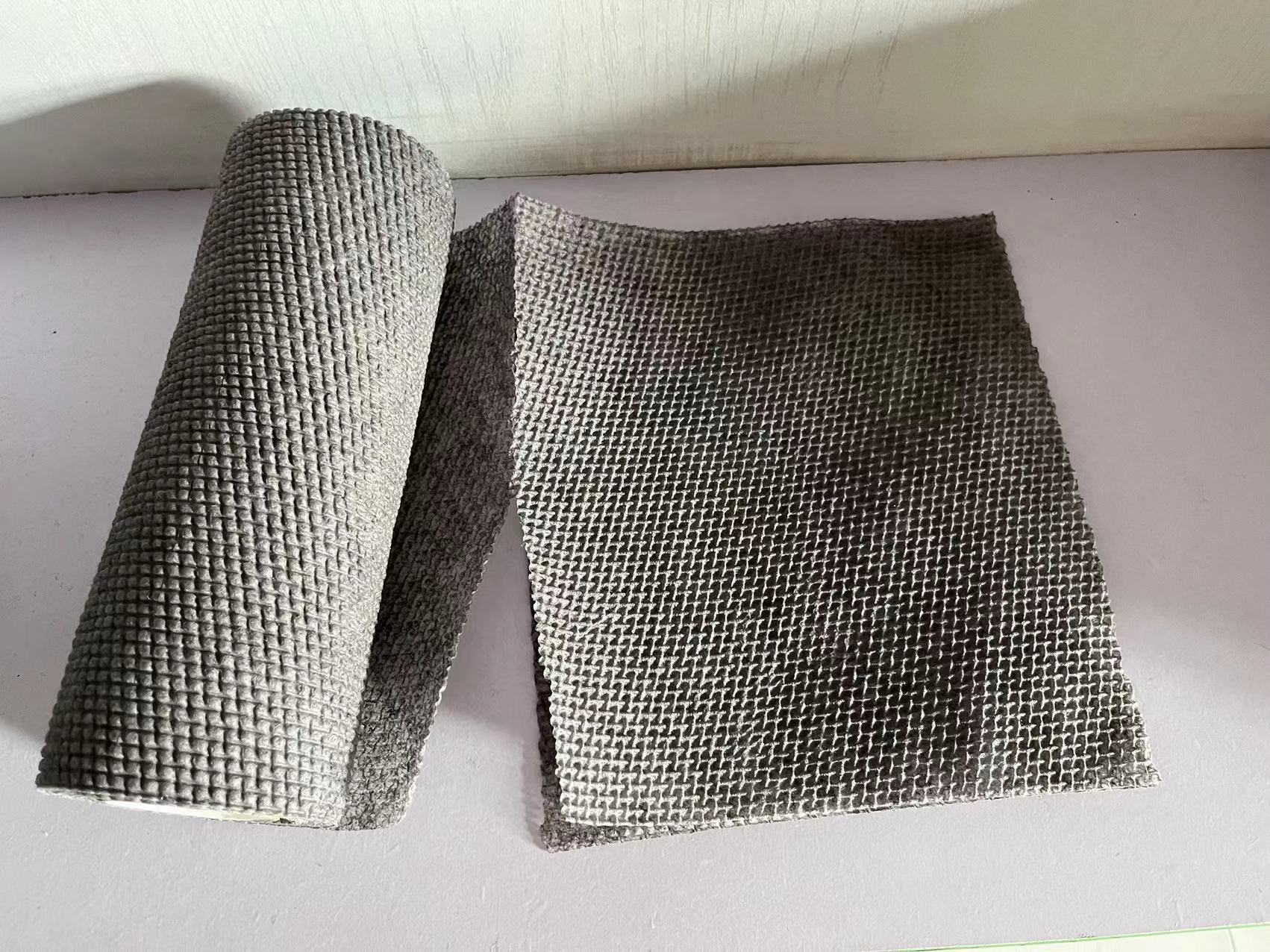

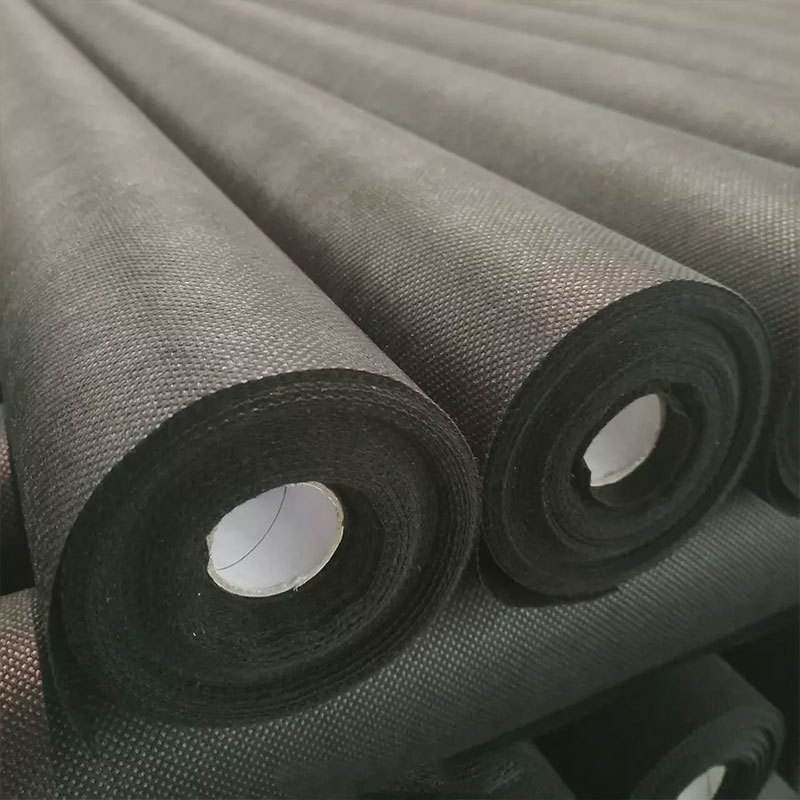

What is PP Nonwoven Fabric?

PP nonwoven fabric is produced by bonding polypropylene fibers together through a variety of processes, including mechanical, thermal, and chemical methods. Unlike traditional woven fabrics, nonwoven fabrics do not require weaving or knitting, making them more cost-effective and efficient to produce. The resulting material is lightweight, strong, and available in various thicknesses and textures, which makes it suitable for a multitude of applications.

Advantages of Using PP Nonwoven Fabric

1. Sustainability and Environmental Impact

In an era where environmental consciousness is paramount, PP nonwoven fabric stands out as a sustainable option. Being made from polypropylene, a thermoplastic polymer, it is recyclable and can be repurposed into new products, significantly reducing waste. Manufacturers can also create biodegradable nonwoven options, which further enhances the environmental benefits.

Additionally, the production of PP nonwoven fabric typically involves less energy and water compared to traditional textiles. This minimal resource consumption aligns with the growing emphasis on sustainable manufacturing practices, making it an attractive choice for eco-conscious businesses.

2. Cost-Effectiveness

One of the most compelling reasons to utilize PP nonwoven fabric is its cost-effectiveness. The manufacturing process is generally simpler and less labor-intensive than that of woven or knitted fabrics. This efficiency translates to lower production costs, which can be advantageous for both manufacturers and consumers.

Moreover, PP nonwoven fabric's durability reduces the need for frequent replacements, further driving down long-term costs. Its lightweight nature also lowers shipping expenses, making it economically viable for businesses looking to streamline their supply chain operations.

3. Durability and Strength

PP nonwoven fabric is renowned for its impressive durability and strength. The fabric can withstand various levels of stress and strain, making it suitable for demanding applications. Its resistance to tearing, stretching, and wear ensures that products made from PP nonwoven fabric maintain their integrity over time.

This durability is particularly beneficial in industries such as construction, agriculture, and healthcare, where reliable materials are crucial. For instance, PP nonwoven fabric is often used in geotextiles, providing soil stabilization and erosion control, showcasing its strength and longevity.

4. Versatility in Applications

The versatility of PP nonwoven fabric is one of its standout features. Its applications span a broad range of industries, including:

- **Medical**: In the healthcare sector, PP nonwoven fabrics are used for surgical gowns, masks, and other protective apparel, providing essential barriers against contaminants.

- **Agricultural**: The fabric serves as an effective mulch and weed control solution, aiding in crop protection and improving yield.

- **Home Goods**: From disposable tablecloths to reusable grocery bags, PP nonwoven fabric is common in everyday household items.

- **Automotive**: In the automotive industry, PP nonwoven materials are employed for interior components, offering lightweight yet durable solutions.

This wide applicability underscores the value of PP nonwoven fabric, as it meets the diverse needs of various sectors.

5. Breathability and Comfort

Another advantage of PP nonwoven fabric is its breathability. The unique structure allows for airflow while simultaneously providing a barrier against moisture and contaminants. This feature makes it an ideal choice for applications where comfort is essential, such as in medical garments and protective clothing.

The fabric's comfort level is crucial for users who require prolonged wear without sacrificing safety. Its soft texture also enhances the overall user experience, making it a preferred option in many sectors.

Applications of PP Nonwoven Fabric

PP nonwoven fabric's vast array of applications highlights its adaptability and functional benefits. Key areas include:

- **Medical Sector**: Used extensively in disposable surgical masks, gowns, and drapes, PP nonwoven fabric plays a vital role in infection control.

- **Filtration**: Its effective filtration capabilities make it suitable for air and liquid filtration systems, enhancing air quality and safety.

- **Construction**: As a geotextile, it aids in soil stabilization, drainage, and erosion control, proving its worth in construction projects.

- **Hygiene Products**: In personal care, PP nonwoven fabric is commonly found in baby diapers, feminine hygiene products, and adult incontinence pads due to its absorbent and soft properties.

- **Packaging**: The fabric is increasingly used in eco-friendly packaging solutions, aligning with modern sustainability trends.

These diverse applications exemplify the versatility of PP nonwoven fabric and its ability to meet specific industry demands.

How to Select the Right PP Nonwoven Fabric

Choosing the right PP nonwoven fabric depends on several factors, including:

- **Application Requirements**: Consider the specific needs of your project. For medical applications, opt for high barrier properties, while agricultural uses may prioritize durability against weather conditions.

- **Thickness and Weight**: The thickness and weight of the fabric can affect its performance. Thicker fabrics offer more strength, while lighter fabrics are more suited for products requiring flexibility.

- **Color and Texture**: Depending on the aesthetic and functional requirements, you may want to select specific colors or textures that align with your brand or product goals.

- **Cost**: Evaluate your budget constraints. While cost-effective, prices can vary based on the properties and manufacturing techniques used for the fabric.

By assessing these criteria, you can select a PP nonwoven fabric that perfectly meets your project’s needs.

The Future of PP Nonwoven Fabric

The future of PP nonwoven fabric looks promising as industries continue to prioritize sustainability and efficiency. Innovations in production methods are expected to enhance the fabric's properties and expand its applications further. Research into biodegradable alternatives and improved recycling processes will likely drive growth in eco-conscious markets.

Additionally, as consumers become more aware of environmental issues, the demand for sustainable products will increase, positioning PP nonwoven fabric as a leading choice for manufacturers across various sectors. Its ability to adapt to changing market needs ensures its relevance in the fabrics industry for years to come.

Conclusion

In summary, the benefits of utilizing PP nonwoven fabric in your projects are vast and varied. From its sustainability and cost-effectiveness to its durability, versatility, and comfort, this innovative material presents exceptional advantages across numerous industries. As businesses continue to seek environmentally friendly and efficient solutions, PP nonwoven fabric is poised to remain a cornerstone in textile applications. Embracing this material not only enhances project outcomes but also aligns with the growing demand for sustainable practices in today’s marketplace.

FAQs about PP Nonwoven Fabric

1. What is the main raw material used in PP nonwoven fabric?

The primary raw material used in PP nonwoven fabric is polypropylene, a type of thermoplastic polymer.

2. Is PP nonwoven fabric eco-friendly?

Yes, PP nonwoven fabric can be eco-friendly, as it is recyclable and can be produced using biodegradable methods, reducing environmental impact.

3. What are the key benefits of using PP nonwoven fabric in medical applications?

In medical applications, PP nonwoven fabric offers excellent barrier properties, comfort, and breathability, making it ideal for protective garments and surgical supplies.

4. How does PP nonwoven fabric compare to other fabrics in terms of durability?

PP nonwoven fabric is highly durable, exhibiting resistance to tearing and wear, making it suitable for demanding environments compared to traditional woven fabrics.

5. Can PP nonwoven fabric be used for outdoor applications?

Yes, PP nonwoven fabric is commonly used in outdoor applications such as landscaping and construction, where its strength and resistance to various environmental factors are beneficial.

By leveraging the advantages of PP nonwoven fabric, businesses can enhance their projects and meet the evolving demands of the market.

PP nonwoven fabric