05

2025

-

07

How to Choose the Right Spunbond Polypropylene Fabric for Your Project

How to Choose the Right Spunbond Polypropylene Fabric for Your Project Understanding Spunbond Polypropylene Fabric Spunbond polypropylene fabric stands out as a versatile non-woven material utilized in various applications, ranging from geotextiles to medical supplies. Made through a unique process that involves the bonding of polypropylene fibers, this fabric offers several advantages such as dur

How to Choose the Right Spunbond Polypropylene Fabric for Your Project

Understanding Spunbond Polypropylene Fabric

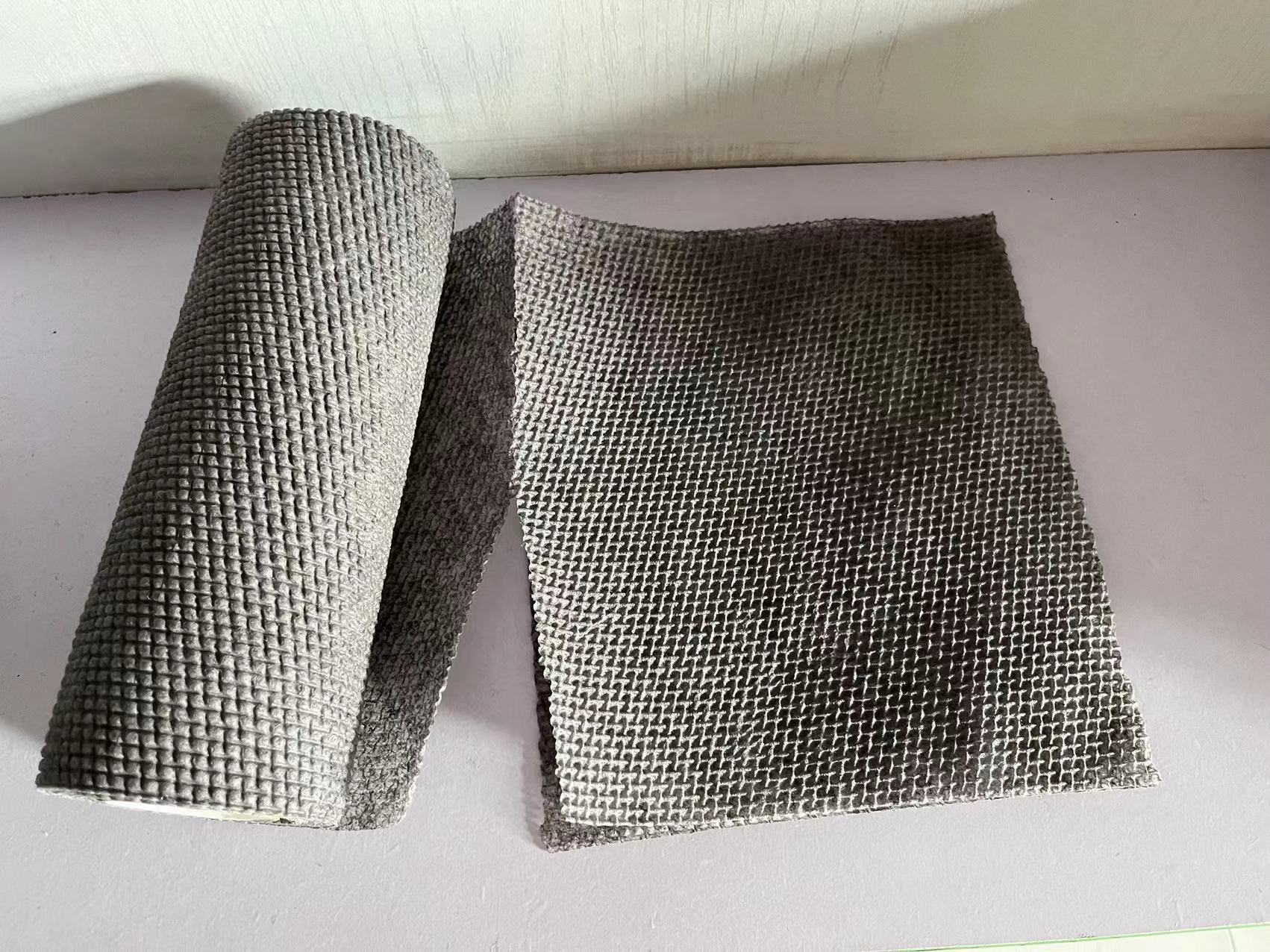

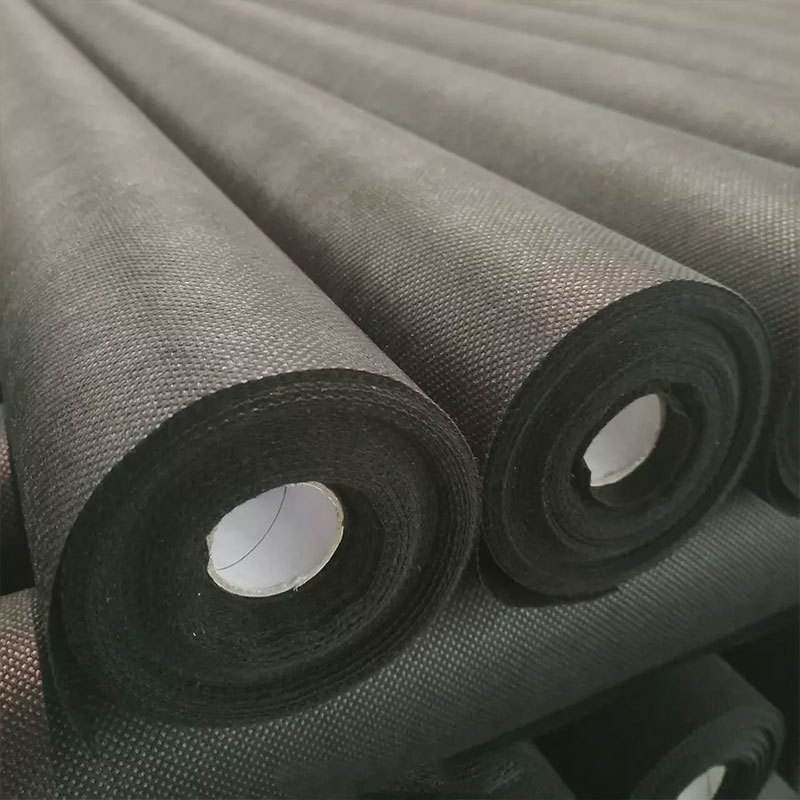

Spunbond polypropylene fabric stands out as a versatile non-woven material utilized in various applications, ranging from geotextiles to medical supplies. Made through a unique process that involves the bonding of polypropylene fibers, this fabric offers several advantages such as durability, lightweight properties, and resistance to moisture and chemicals. In this section, we will dive deeper into the characteristics that make spunbond polypropylene fabric an ideal choice for numerous projects.

What Makes Spunbond Polypropylene Unique?

Spunbond polypropylene fabric is characterized by its unique production method, which involves extruding polypropylene into filaments and then bonding the fibers to create a fabric. This process results in a material that is both robust and breathable. The non-woven structure allows for enhanced filtration and drainage properties, making it perfect for applications that require air and moisture permeability.

Applications of Spunbond Polypropylene Fabric

The versatility of spunbond polypropylene fabric means it can be used in various industries, including:

- **Agriculture**: As a protective cover for crops or as landscape fabric.

- **Medical Supplies**: In the production of surgical gowns, masks, and drapes.

- **Construction**: For geotextile applications, moisture barriers, and building wraps.

- **Home Décor**: In the making of decorative items, bags, and upholstery.

- **Automotive**: In interior linings and insulation.

This range of applications illustrates the potential of spunbond polypropylene fabric for various projects.

Key Factors to Consider When Choosing Spunbond Polypropylene Fabric

Selecting the right spunbond polypropylene fabric for your project requires a thorough understanding of several critical factors. Here, we will outline the key elements that should guide your decision-making process.

1. Fabric Weight and Thickness

The weight and thickness of spunbond polypropylene fabric play a crucial role in its performance. Measured in grams per square meter (GSM), the fabric's weight will influence its strength and durability. Lighter weights (around 10-30 GSM) are suitable for applications that require flexibility, while heavier weights (up to 100 GSM) are ideal for more demanding uses, such as construction or medical applications.

2. Color and Aesthetics

The aesthetic appeal of spunbond polypropylene fabric can vary significantly, and color options are abundant. Consider the visual requirements of your project. White and black are common choices, but manufacturers offer a spectrum of colors. Choosing the right color can enhance the overall appearance of your product, especially in consumer-facing applications.

3. Chemical Resistance

Different projects may expose the fabric to various chemicals. Assess the environmental conditions and potential chemicals that the fabric may come into contact with. Spunbond polypropylene fabric generally exhibits excellent resistance to many acids and bases, making it a reliable choice for industrial applications.

4. UV Resistance

For outdoor applications, UV resistance becomes a significant factor to consider. Prolonged exposure to sunlight can degrade materials over time. Look for spunbond polypropylene fabric that is treated for UV resistance if your project will be exposed to direct sunlight for extended periods.

5. Breathability

Breathability is essential for applications such as agricultural covers and medical textiles. Ensure that the spunbond polypropylene fabric you choose has adequate airflow properties to promote ventilation and moisture management.

6. Eco-Friendliness

With increasing awareness of environmental impacts, consider the eco-friendliness of the spunbond polypropylene fabric. Many manufacturers now produce recyclable or biodegradable options. Selecting an environmentally responsible product can enhance your brand's reputation and appeal to eco-conscious consumers.

7. Cost-Effectiveness

Budget constraints are always a consideration when selecting materials. Compare prices across different suppliers and evaluate the fabric’s performance relative to its cost. While it may be tempting to choose the cheapest option, investing in high-quality spunbond polypropylene fabric can lead to better long-term results and reduced material waste.

Where to Source Quality Spunbond Polypropylene Fabric

Finding a reliable supplier is critical to ensuring that you obtain high-quality spunbond polypropylene fabric. Here are some tips for sourcing the right material:

1. Research Reputable Manufacturers

Conduct thorough research to identify reputable manufacturers who specialize in spunbond polypropylene fabric. Look for companies with positive reviews, industry certifications, and a track record of delivering quality products.

2. Request Samples

Before making a bulk purchase, request fabric samples from potential suppliers. This step allows you to assess the material’s quality, weight, and other characteristics firsthand.

3. Check for Compliance and Certifications

Ensure the spunbond polypropylene fabric complies with relevant industry standards and regulations. Certifications can provide assurance of the material's quality and safety.

Testing Your Spunbond Polypropylene Fabric

Once you have selected your spunbond polypropylene fabric, conducting thorough testing is essential to confirm its suitability for your specific application.

1. Lab Testing for Strength and Durability

Consider subjecting the fabric to lab testing to assess its tensile strength, tear resistance, and durability. This data will help you understand how the fabric will perform under real-world conditions.

2. Field Testing

If possible, conduct field tests by using the fabric in a small-scale project. This approach will provide practical insights into how the material holds up in actual conditions.

Maintenance and Care of Spunbond Polypropylene Fabric

Proper maintenance can significantly extend the life of spunbond polypropylene fabric. Here are some tips for care:

1. Cleaning Techniques

For general cleaning, a gentle soap solution and water can be used. Avoid harsh chemicals that may damage the fabric's integrity.

2. Storage Practices

Store spunbond polypropylene fabric in a cool, dry place away from direct sunlight. Proper storage prevents degradation and maintains the fabric's quality over time.

3. Monitoring for Wear and Tear

Regularly inspect the fabric for signs of wear and tear, especially in high-stress applications. Early detection allows for timely repairs or replacements.

Common Mistakes to Avoid When Choosing Spunbond Polypropylene Fabric

Making informed decisions is vital. Here are some common pitfalls to avoid:

1. Ignoring Application Requirements

Focusing solely on price without considering the specific requirements of your application can lead to subpar performance. Always prioritize the fabric’s characteristics that align with your project needs.

2. Overlooking Supplier Reputation

Purchasing from unknown or unverified suppliers can result in receiving low-quality materials. Invest time in researching and selecting established manufacturers.

3. Neglecting Long-Term Costs

While it might be tempting to choose the lowest-priced option, consider the long-term costs associated with durability and maintenance. Sometimes, investing more upfront can save money in the long run.

Frequently Asked Questions (FAQs)

1. What is the difference between spunbond and meltblown polypropylene fabric?

Spunbond polypropylene fabric is made through the continuous filament process, resulting in a strong, durable material suitable for various applications. In contrast, meltblown polypropylene fabric consists of finer fibers, providing excellent filtration properties but typically weaker structural integrity.

2. Can spunbond polypropylene fabric be recycled?

Yes, many spunbond polypropylene fabrics are recyclable. Be sure to check with local recycling programs for specific guidelines.

3. Is spunbond polypropylene fabric waterproof?

Spunbond polypropylene fabric has water-resistant properties, but it is not entirely waterproof. For applications requiring complete waterproofing, consider additional treatments or coatings.

4. How does spunbond polypropylene fabric compare in cost to other fabrics?

Spunbond polypropylene fabric is generally cost-effective compared to other textiles, particularly in applications where durability and performance are critical. Pricing can vary based on weight and treatment options.

5. Are there any health concerns associated with spunbond polypropylene fabric?

Spunbond polypropylene fabric is widely regarded as safe for use in various applications, including medical textiles. However, always ensure that the fabric meets the necessary safety standards for your specific use case.

Conclusion

Choosing the right spunbond polypropylene fabric for your project involves understanding the unique characteristics of the material and meticulously evaluating your project's requirements. By considering factors such as weight, color, chemical resistance, UV protection, and eco-friendliness, you can make an informed decision that maximizes performance and cost-effectiveness. Additionally, sourcing from reputable manufacturers, conducting thorough testing, and ensuring proper maintenance will further enhance the longevity and success of your project. With the insights provided in this guide, you are well-equipped to select the perfect spunbond polypropylene fabric to meet your needs.

spunbond polypropylene fabric

Prev