10

2025

-

07

Understanding Spunbond Nonwoven Fabric: Characteristics and Applications

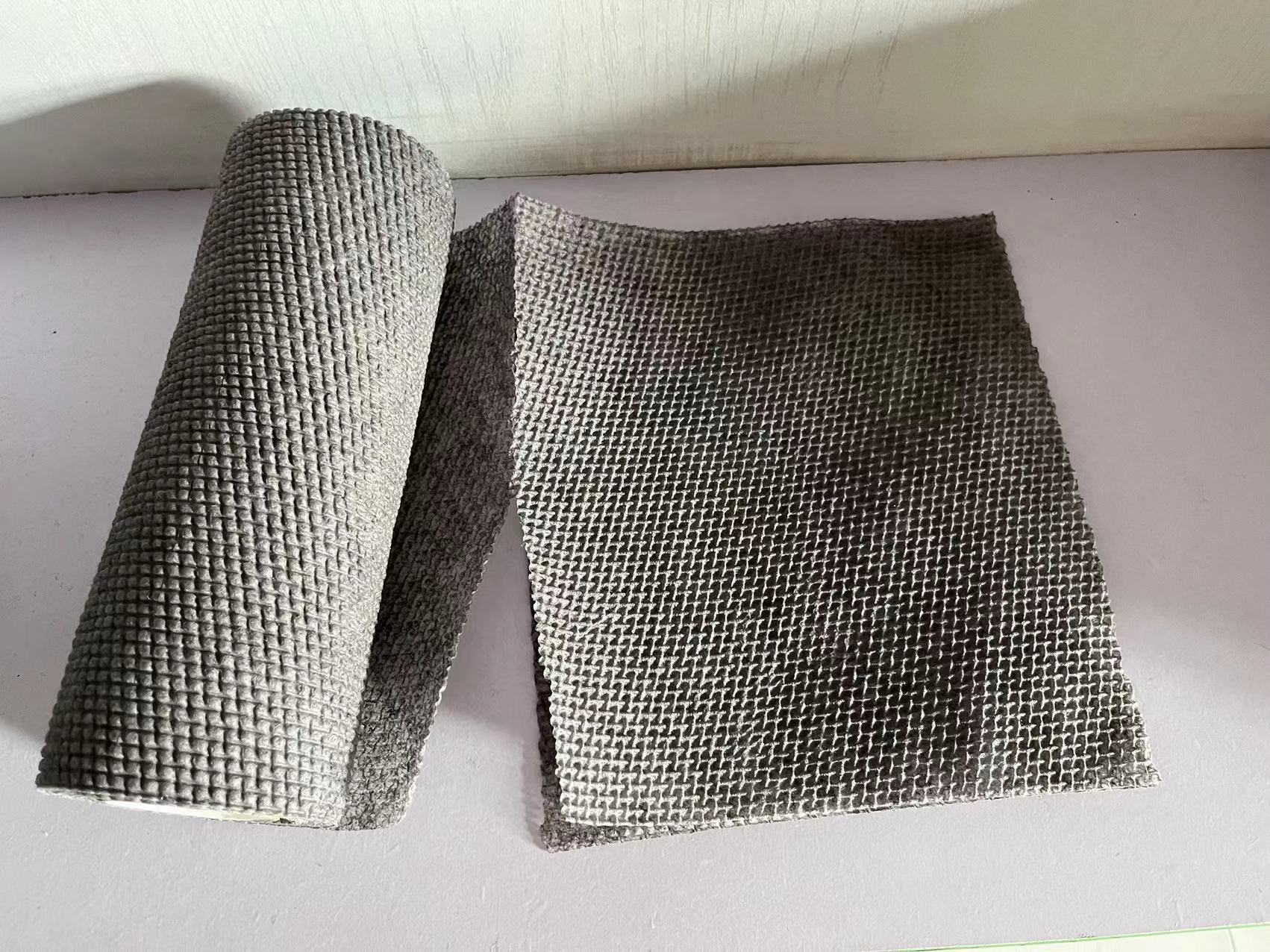

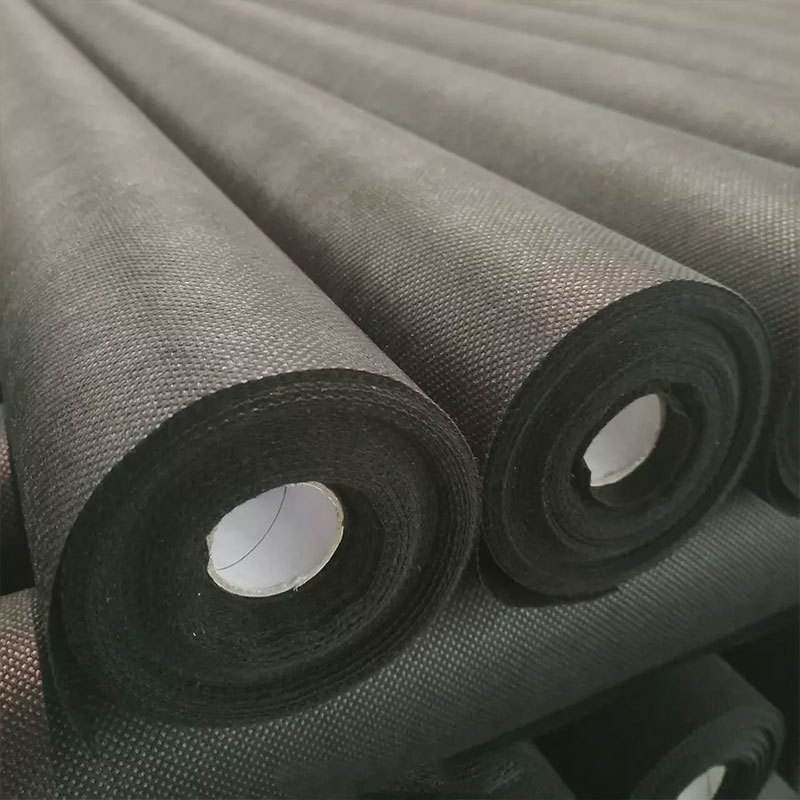

Spunbond nonwoven fabric has become an essential material in the textile industry due to its unique characteristics and versatility. This type of fabric is produced through a process that involves spinning continuous filaments of polymer into a web-like structure, which is then bonded together using heat, pressure, or adhesive methods. The result is a durable, lightweight fabric that offers variou

Spunbond nonwoven fabric has become an essential material in the textile industry due to its unique characteristics and versatility. This type of fabric is produced through a process that involves spinning continuous filaments of polymer into a web-like structure, which is then bonded together using heat, pressure, or adhesive methods. The result is a durable, lightweight fabric that offers various benefits.

One of the primary advantages of spunbond nonwoven fabric is its strength. The continuous filaments enhance the fabric's tensile strength, making it suitable for applications that require durability. Additionally, the fabric is resistant to tearing and puncturing, giving it an edge over traditional woven fabrics in specific uses like medical garments, geotextiles, and industrial applications.

Another notable characteristic of spunbond nonwoven fabric is its breathability. The fabric allows air and moisture to pass through, which is particularly advantageous in applications such as hygiene products, where breathability contributes to comfort. This property also makes it ideal for agricultural uses, such as crop covers, where it helps protect plants from harsh weather while allowing sunlight and water to reach them.

Furthermore, spunbond nonwoven fabric is relatively lightweight, making it easy to handle and transport. Its low weight and inherent strength make it an excellent choice for products that require both durability and ease of use. Additionally, this fabric can be produced in various colors and finishes, allowing for customization to meet specific design needs.

The manufacturing process of spunbond nonwoven fabric is efficient and environmentally friendly. It typically involves using thermoplastic polymers, which can be recycled. This aspect contributes to sustainability in the textile industry, as manufacturers increasingly seek eco-friendly alternatives.

Spunbond nonwoven fabric finds its applications in multiple sectors. In the medical field, it is commonly used for surgical gowns, masks, and other personal protective equipment. These items require high levels of hygiene and protection, making spunbond an ideal material. In agriculture, it is used for crop protection, soil stabilization, and weed control fabrics. In the automotive industry, it can be found in insulation, soundproofing, and interior lining materials.

In conclusion, spunbond nonwoven fabric stands out in the textile industry due to its strength, breathability, and versatility. Its wide range of applications across various sectors highlights its importance and utility in modern manufacturing processes. As technology advances, the potential for new applications and improvements in spunbond fabric continues to grow, making it a material to watch in the evolving landscape of textiles.

One of the primary advantages of spunbond nonwoven fabric is its strength. The continuous filaments enhance the fabric's tensile strength, making it suitable for applications that require durability. Additionally, the fabric is resistant to tearing and puncturing, giving it an edge over traditional woven fabrics in specific uses like medical garments, geotextiles, and industrial applications.

Another notable characteristic of spunbond nonwoven fabric is its breathability. The fabric allows air and moisture to pass through, which is particularly advantageous in applications such as hygiene products, where breathability contributes to comfort. This property also makes it ideal for agricultural uses, such as crop covers, where it helps protect plants from harsh weather while allowing sunlight and water to reach them.

Furthermore, spunbond nonwoven fabric is relatively lightweight, making it easy to handle and transport. Its low weight and inherent strength make it an excellent choice for products that require both durability and ease of use. Additionally, this fabric can be produced in various colors and finishes, allowing for customization to meet specific design needs.

The manufacturing process of spunbond nonwoven fabric is efficient and environmentally friendly. It typically involves using thermoplastic polymers, which can be recycled. This aspect contributes to sustainability in the textile industry, as manufacturers increasingly seek eco-friendly alternatives.

Spunbond nonwoven fabric finds its applications in multiple sectors. In the medical field, it is commonly used for surgical gowns, masks, and other personal protective equipment. These items require high levels of hygiene and protection, making spunbond an ideal material. In agriculture, it is used for crop protection, soil stabilization, and weed control fabrics. In the automotive industry, it can be found in insulation, soundproofing, and interior lining materials.

In conclusion, spunbond nonwoven fabric stands out in the textile industry due to its strength, breathability, and versatility. Its wide range of applications across various sectors highlights its importance and utility in modern manufacturing processes. As technology advances, the potential for new applications and improvements in spunbond fabric continues to grow, making it a material to watch in the evolving landscape of textiles.

spunbond nonwoven fabric