09

2025

-

08

Understanding Spunbond Nonwoven Fabric: Applications and Advantages

Spunbond nonwoven fabric represents a significant innovation in the textile industry, characterized by its unique structure and versatile applications. This category of nonwoven fabric is manufactured primarily through a process that involves the melting of thermoplastic polymers, which are then extruded into filaments. These filaments are laid down in a web-like structure, and subsequently bonded

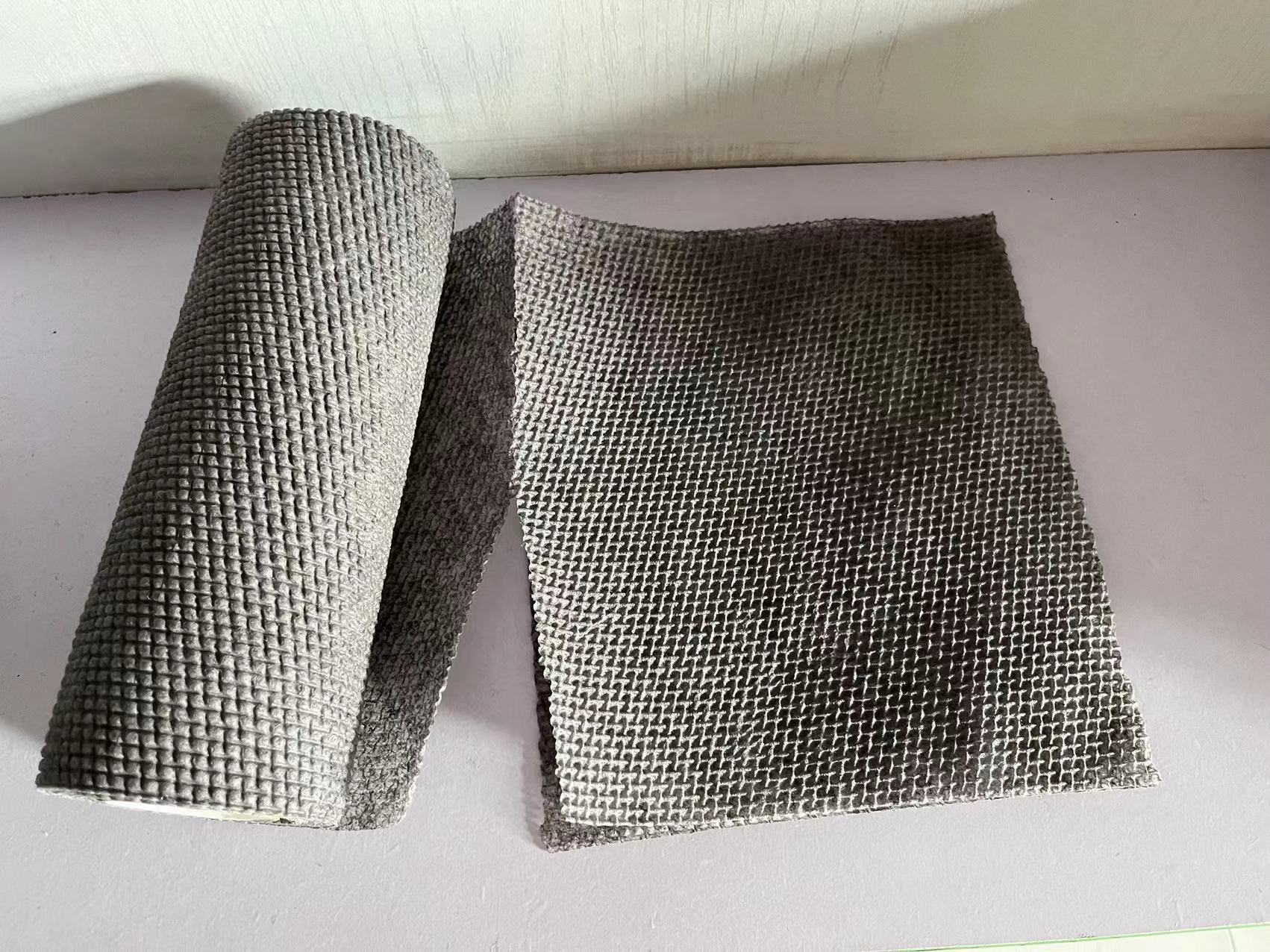

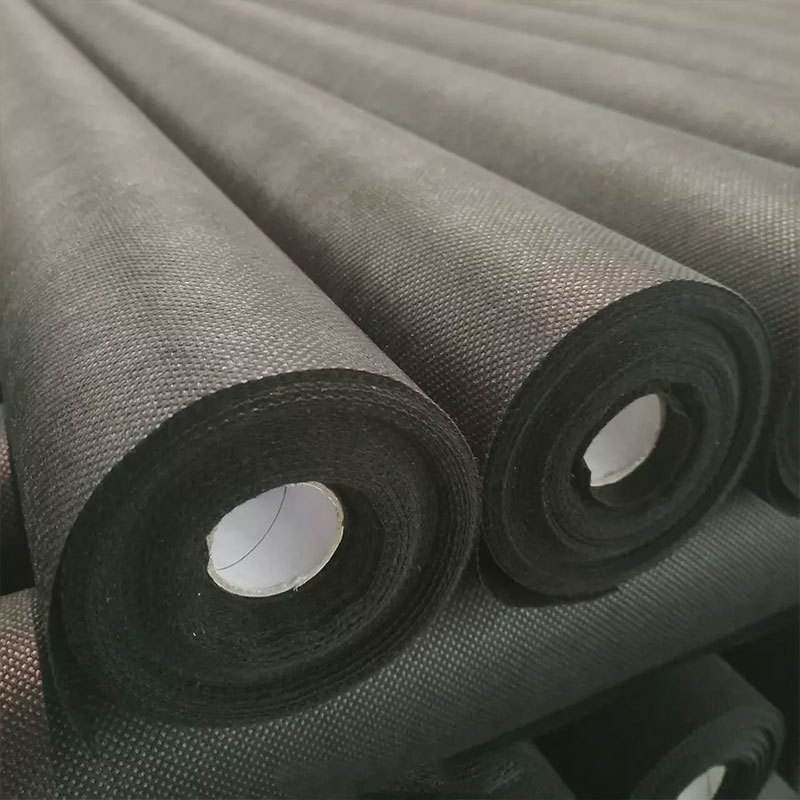

Spunbond nonwoven fabric represents a significant innovation in the textile industry, characterized by its unique structure and versatile applications. This category of nonwoven fabric is manufactured primarily through a process that involves the melting of thermoplastic polymers, which are then extruded into filaments. These filaments are laid down in a web-like structure, and subsequently bonded together through heat, pressure, or adhesives. The result is a lightweight yet durable fabric that boasts a range of properties making it suitable for various applications.

One of the standout features of spunbond nonwoven fabric is its high tensile strength. This is attributed to the continuous filaments used in its production, which provide excellent durability and resistance to tearing. As a result, spunbond fabrics are ideal for applications requiring robust materials, such as in protective clothing, medical fabrics, and geotextiles. Furthermore, their resistance to water, chemicals, and UV light enhances their performance in outdoor and industrial applications.

Additionally, spunbond nonwoven fabrics are known for their breathability and drapability, which makes them suitable for products like agricultural covers and hygiene products. In the realm of hygiene, they are widely used in the manufacture of disposable diapers, feminine hygiene products, and surgical gowns, where comfort and fluid resistance are paramount. The ability to produce spunbond fabrics in various weights and thicknesses allows manufacturers to tailor these materials for specific uses, further enhancing their appeal.

From an environmental perspective, the production of spunbond nonwoven fabrics can be optimized to reduce waste and improve sustainability. Many manufacturers are now adopting eco-friendly practices, such as using recycled materials and minimizing energy consumption during production. This shift not only aligns with global trends toward sustainability but also meets the growing demand for environmentally conscious products in various sectors.

In conclusion, spunbond nonwoven fabric is a versatile and innovative material that plays a crucial role in many industries. Its unique manufacturing process, coupled with advantageous properties like strength, breathability, and resistance to chemicals, underscores its value in applications ranging from medical to agricultural uses. As manufacturers continue to enhance production techniques and focus on sustainability, the potential for spunbond nonwoven fabric will only grow, making it a key player in the textile landscape. Whether you are in the textile industry or exploring the possibilities of nonwoven materials, understanding spunbond fabrics can provide insights into their significant impact and benefits.

One of the standout features of spunbond nonwoven fabric is its high tensile strength. This is attributed to the continuous filaments used in its production, which provide excellent durability and resistance to tearing. As a result, spunbond fabrics are ideal for applications requiring robust materials, such as in protective clothing, medical fabrics, and geotextiles. Furthermore, their resistance to water, chemicals, and UV light enhances their performance in outdoor and industrial applications.

Additionally, spunbond nonwoven fabrics are known for their breathability and drapability, which makes them suitable for products like agricultural covers and hygiene products. In the realm of hygiene, they are widely used in the manufacture of disposable diapers, feminine hygiene products, and surgical gowns, where comfort and fluid resistance are paramount. The ability to produce spunbond fabrics in various weights and thicknesses allows manufacturers to tailor these materials for specific uses, further enhancing their appeal.

From an environmental perspective, the production of spunbond nonwoven fabrics can be optimized to reduce waste and improve sustainability. Many manufacturers are now adopting eco-friendly practices, such as using recycled materials and minimizing energy consumption during production. This shift not only aligns with global trends toward sustainability but also meets the growing demand for environmentally conscious products in various sectors.

In conclusion, spunbond nonwoven fabric is a versatile and innovative material that plays a crucial role in many industries. Its unique manufacturing process, coupled with advantageous properties like strength, breathability, and resistance to chemicals, underscores its value in applications ranging from medical to agricultural uses. As manufacturers continue to enhance production techniques and focus on sustainability, the potential for spunbond nonwoven fabric will only grow, making it a key player in the textile landscape. Whether you are in the textile industry or exploring the possibilities of nonwoven materials, understanding spunbond fabrics can provide insights into their significant impact and benefits.

spunbond nonwoven fabric