12

2025

-

06

Understanding PP Spunbond Nonwoven Fabric: A Comprehensive Guide

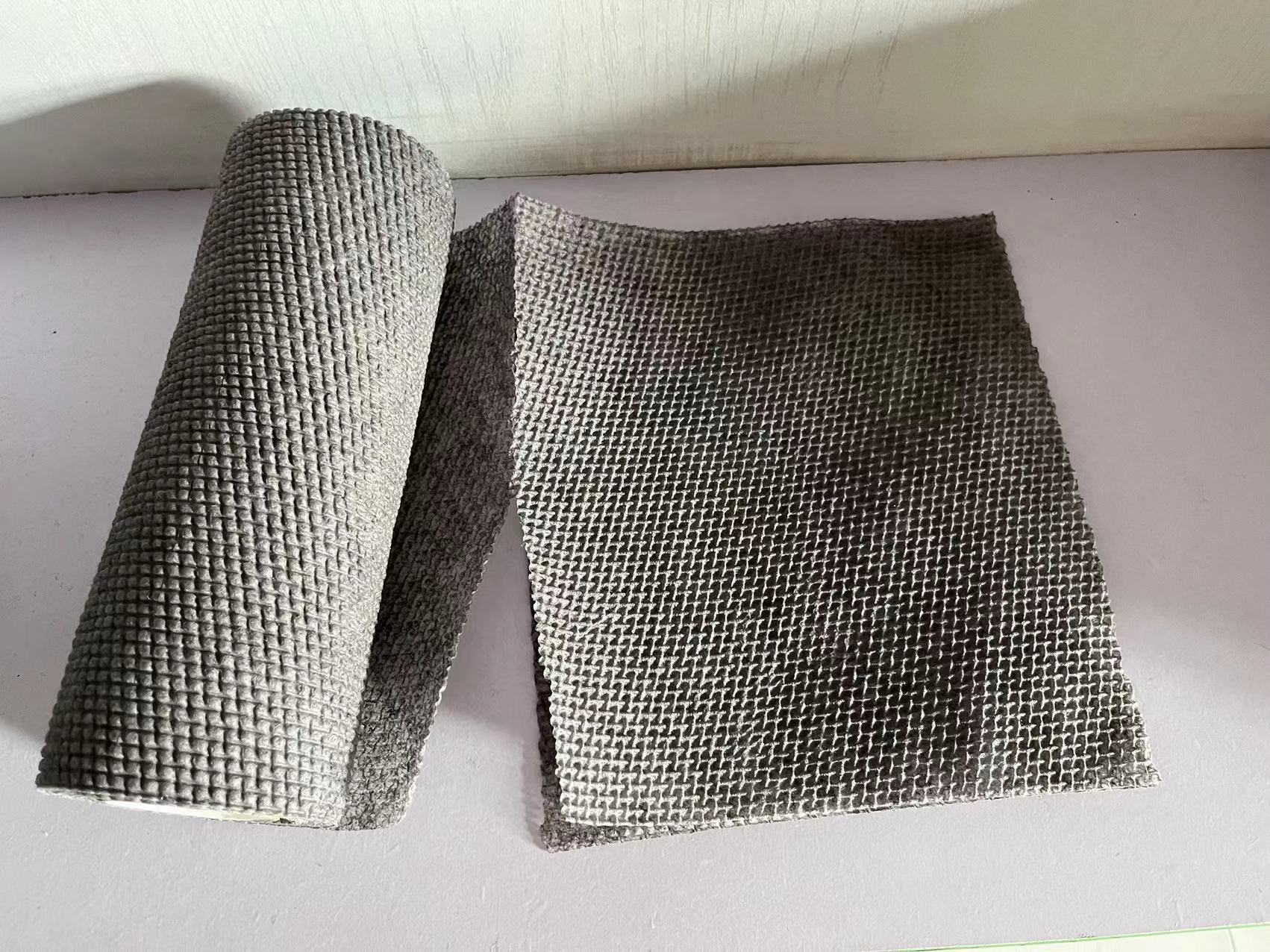

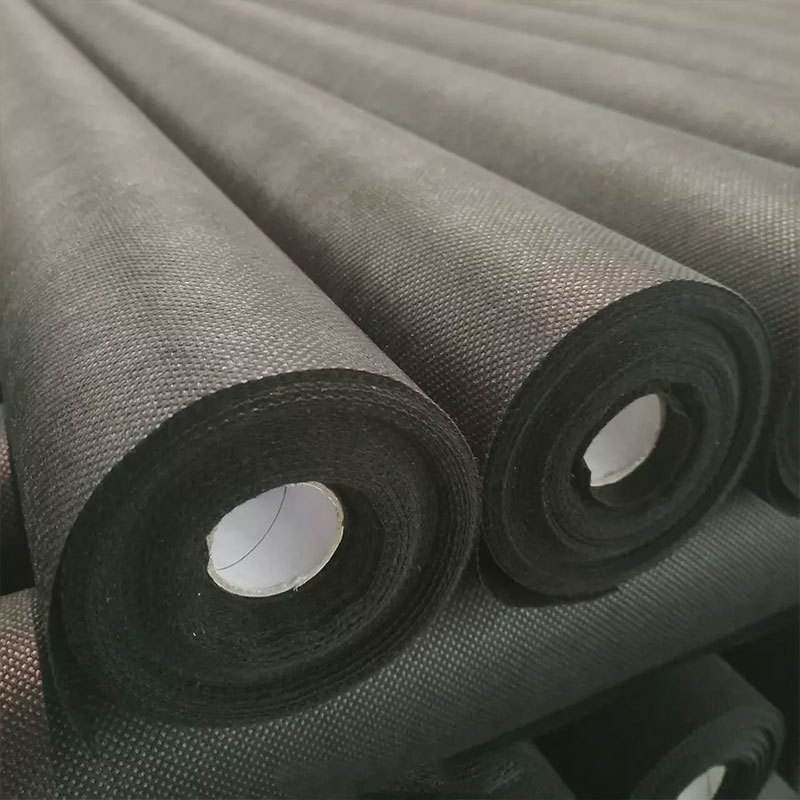

PP spunbond nonwoven fabric is a widely utilized material in the textile industry, known for its unique properties and functionalities. Made from polypropylene, this type of nonwoven fabric is created through a process that involves the continuous filament being spun and bonded together, resulting in a strong and durable fabric. Its lightweight nature, combined with excellent tensile strength, mak

PP spunbond nonwoven fabric is a widely utilized material in the textile industry, known for its unique properties and functionalities. Made from polypropylene, this type of nonwoven fabric is created through a process that involves the continuous filament being spun and bonded together, resulting in a strong and durable fabric. Its lightweight nature, combined with excellent tensile strength, makes it suitable for a multitude of applications.

One of the key characteristics of PP spunbond nonwoven fabric is its breathability. This allows air and moisture to pass through, making it an ideal choice for products that require ventilation, such as surgical gowns, masks, and hygiene products. Additionally, the fabric is resistant to various chemicals and is UV stabilized, which enhances its durability and longevity, particularly when used in outdoor applications.

The manufacturing process of PP spunbond nonwoven fabric is efficient and environmentally friendly. The process begins with melting polypropylene pellets, which are then extruded into filaments. These filaments are subsequently laid out in a random pattern and bonded together through thermal, mechanical, or chemical methods. This results in a fabric that is not only strong but also lightweight and cost-effective, making it a preferred choice for many industries.

In terms of applications, PP spunbond nonwoven fabric is incredibly versatile. It is commonly used in medical and healthcare settings for products such as surgical drapes, gowns, and masks due to its barrier properties and comfort. The automotive industry also employs this fabric for interior linings, soundproofing, and insulation materials. Furthermore, in the agricultural sector, it is used to create protective covers for plants and crops, aiding in temperature regulation and pest control.

Another significant advantage of PP spunbond nonwoven fabric is its ease of processing. It can be easily cut, sewn, or printed on, which allows for customization in design and functionality. Additionally, it can be produced in various colors and thicknesses to meet specific requirements, making it a flexible solution for manufacturers and retailers alike.

In conclusion, PP spunbond nonwoven fabric stands out as a crucial material in the textile industry, owing to its remarkable properties and adaptability. Understanding its manufacturing process and applications can help professionals make informed decisions when it comes to sourcing materials for diverse projects. Whether for medical, automotive, or agricultural use, this fabric continues to play a vital role in innovation and efficiency across various sectors.

One of the key characteristics of PP spunbond nonwoven fabric is its breathability. This allows air and moisture to pass through, making it an ideal choice for products that require ventilation, such as surgical gowns, masks, and hygiene products. Additionally, the fabric is resistant to various chemicals and is UV stabilized, which enhances its durability and longevity, particularly when used in outdoor applications.

The manufacturing process of PP spunbond nonwoven fabric is efficient and environmentally friendly. The process begins with melting polypropylene pellets, which are then extruded into filaments. These filaments are subsequently laid out in a random pattern and bonded together through thermal, mechanical, or chemical methods. This results in a fabric that is not only strong but also lightweight and cost-effective, making it a preferred choice for many industries.

In terms of applications, PP spunbond nonwoven fabric is incredibly versatile. It is commonly used in medical and healthcare settings for products such as surgical drapes, gowns, and masks due to its barrier properties and comfort. The automotive industry also employs this fabric for interior linings, soundproofing, and insulation materials. Furthermore, in the agricultural sector, it is used to create protective covers for plants and crops, aiding in temperature regulation and pest control.

Another significant advantage of PP spunbond nonwoven fabric is its ease of processing. It can be easily cut, sewn, or printed on, which allows for customization in design and functionality. Additionally, it can be produced in various colors and thicknesses to meet specific requirements, making it a flexible solution for manufacturers and retailers alike.

In conclusion, PP spunbond nonwoven fabric stands out as a crucial material in the textile industry, owing to its remarkable properties and adaptability. Understanding its manufacturing process and applications can help professionals make informed decisions when it comes to sourcing materials for diverse projects. Whether for medical, automotive, or agricultural use, this fabric continues to play a vital role in innovation and efficiency across various sectors.

pp spunbond nonwoven fabric