12

2025

-

07

Exploring the Versatility of PP Spunbond Nonwoven Fabric

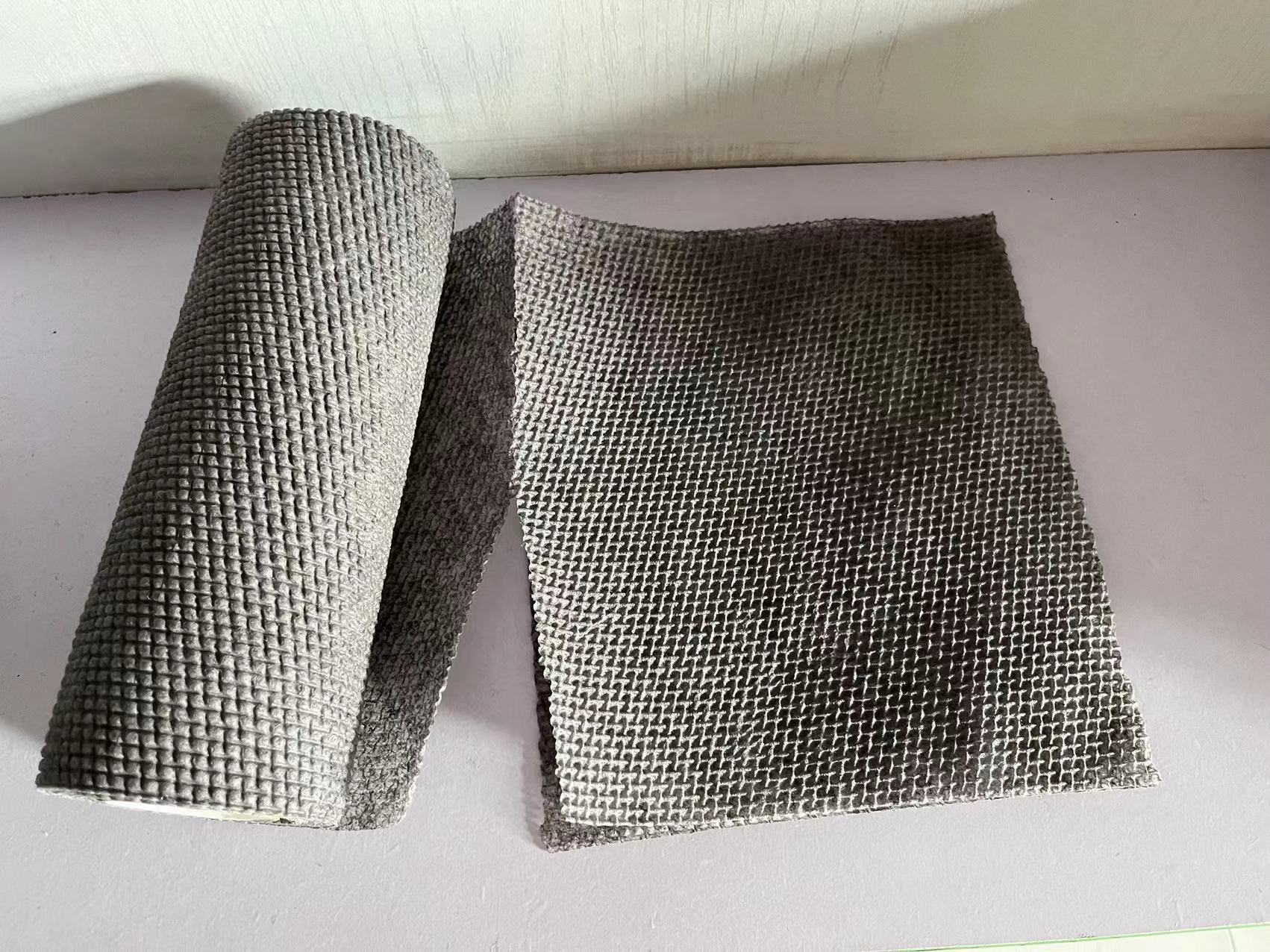

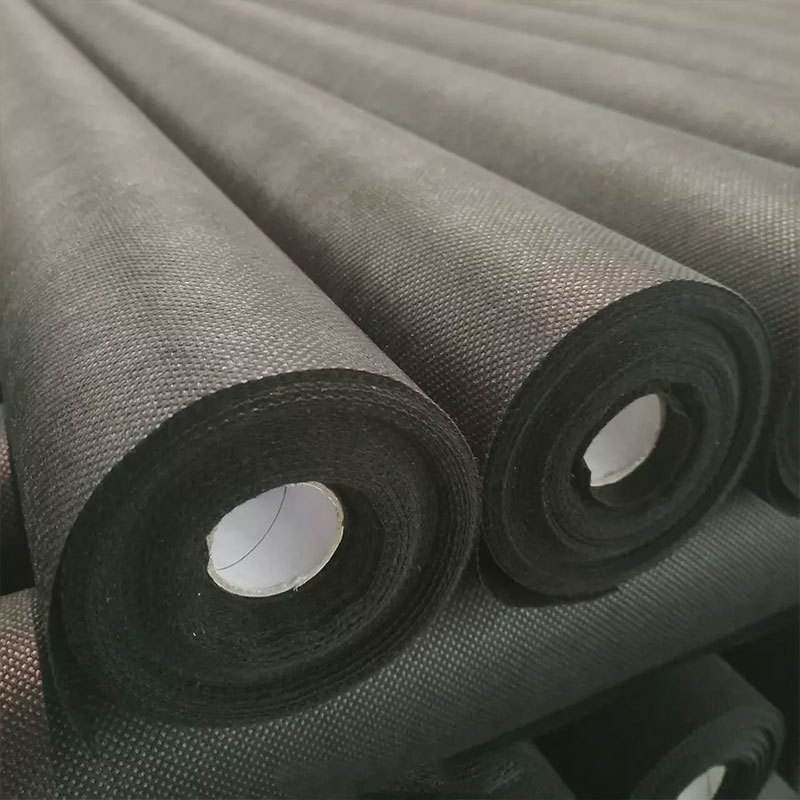

Polypropylene (PP) spunbond nonwoven fabric has emerged as a crucial material in the textile industry, thanks to its unique properties and versatility. Produced through a process of melting polypropylene and then spinning it into fine filaments, this nonwoven fabric offers a range of benefits that make it suitable for various applications. One of the primary advantages of PP spunbond nonwoven fabr

Polypropylene (PP) spunbond nonwoven fabric has emerged as a crucial material in the textile industry, thanks to its unique properties and versatility. Produced through a process of melting polypropylene and then spinning it into fine filaments, this nonwoven fabric offers a range of benefits that make it suitable for various applications.

One of the primary advantages of PP spunbond nonwoven fabric is its lightweight nature. This characteristic ensures ease of handling and transportation, making it ideal for products that require both durability and comfort. Additionally, the fabric is designed to be breathable, which is particularly beneficial in applications where moisture management is essential.

The manufacturing process of PP spunbond nonwoven fabric involves extruding polypropylene fibers, which are then laid down in a web-like structure. This process not only contributes to the fabric's strength but also enhances its stability, ensuring that it can withstand various environmental conditions. As a result, the fabric is resistant to tearing and has a long lifespan, making it a cost-effective choice for many industries.

Another significant feature of PP spunbond nonwoven fabric is its resistance to chemicals and biological agents. This property makes it suitable for medical and hygiene products, such as surgical gowns, masks, and disposable bedding, where sterility and hygiene are paramount. Furthermore, its ability to be treated with various finishes allows for the development of specialized fabrics tailored to specific needs, such as water repellency or UV resistance.

The eco-friendliness of PP spunbond nonwoven fabric is also worth noting. It is recyclable and can be produced using sustainable practices, which appeals to environmentally conscious consumers and businesses alike. As the demand for sustainable products continues to rise, the role of PP spunbond nonwoven fabric in promoting eco-friendly practices cannot be overstated.

In the automotive industry, this fabric is used for upholstery, sound insulation, and as a protective barrier. Its durability and lightweight properties contribute to improved fuel efficiency while maintaining high performance standards. Similarly, in the construction sector, PP spunbond nonwoven fabric serves as a reliable material for roofing and geotextiles, providing essential protection against moisture and soil erosion.

In summary, PP spunbond nonwoven fabric stands out for its lightweight, durable, and versatile nature, making it an invaluable material across various industries, including healthcare, automotive, and construction. Its unique properties not only enhance product performance but also align with sustainability goals, paving the way for more responsible consumption in the textile market.

One of the primary advantages of PP spunbond nonwoven fabric is its lightweight nature. This characteristic ensures ease of handling and transportation, making it ideal for products that require both durability and comfort. Additionally, the fabric is designed to be breathable, which is particularly beneficial in applications where moisture management is essential.

The manufacturing process of PP spunbond nonwoven fabric involves extruding polypropylene fibers, which are then laid down in a web-like structure. This process not only contributes to the fabric's strength but also enhances its stability, ensuring that it can withstand various environmental conditions. As a result, the fabric is resistant to tearing and has a long lifespan, making it a cost-effective choice for many industries.

Another significant feature of PP spunbond nonwoven fabric is its resistance to chemicals and biological agents. This property makes it suitable for medical and hygiene products, such as surgical gowns, masks, and disposable bedding, where sterility and hygiene are paramount. Furthermore, its ability to be treated with various finishes allows for the development of specialized fabrics tailored to specific needs, such as water repellency or UV resistance.

The eco-friendliness of PP spunbond nonwoven fabric is also worth noting. It is recyclable and can be produced using sustainable practices, which appeals to environmentally conscious consumers and businesses alike. As the demand for sustainable products continues to rise, the role of PP spunbond nonwoven fabric in promoting eco-friendly practices cannot be overstated.

In the automotive industry, this fabric is used for upholstery, sound insulation, and as a protective barrier. Its durability and lightweight properties contribute to improved fuel efficiency while maintaining high performance standards. Similarly, in the construction sector, PP spunbond nonwoven fabric serves as a reliable material for roofing and geotextiles, providing essential protection against moisture and soil erosion.

In summary, PP spunbond nonwoven fabric stands out for its lightweight, durable, and versatile nature, making it an invaluable material across various industries, including healthcare, automotive, and construction. Its unique properties not only enhance product performance but also align with sustainability goals, paving the way for more responsible consumption in the textile market.

pp spunbond nonwoven fabric