20

2025

-

07

Understanding Spunbond Polypropylene Fabric: Key Insights for the Nonwoven Textile Industry

Spunbond polypropylene fabric is a versatile nonwoven material widely used in various applications, from medical textiles to household products. Understanding its properties, production techniques, and potential uses can significantly benefit businesses in the textile industry. One of the most notable features of spunbond polypropylene fabric is its strength and durability. This fabric is created

Spunbond polypropylene fabric is a versatile nonwoven material widely used in various applications, from medical textiles to household products. Understanding its properties, production techniques, and potential uses can significantly benefit businesses in the textile industry.

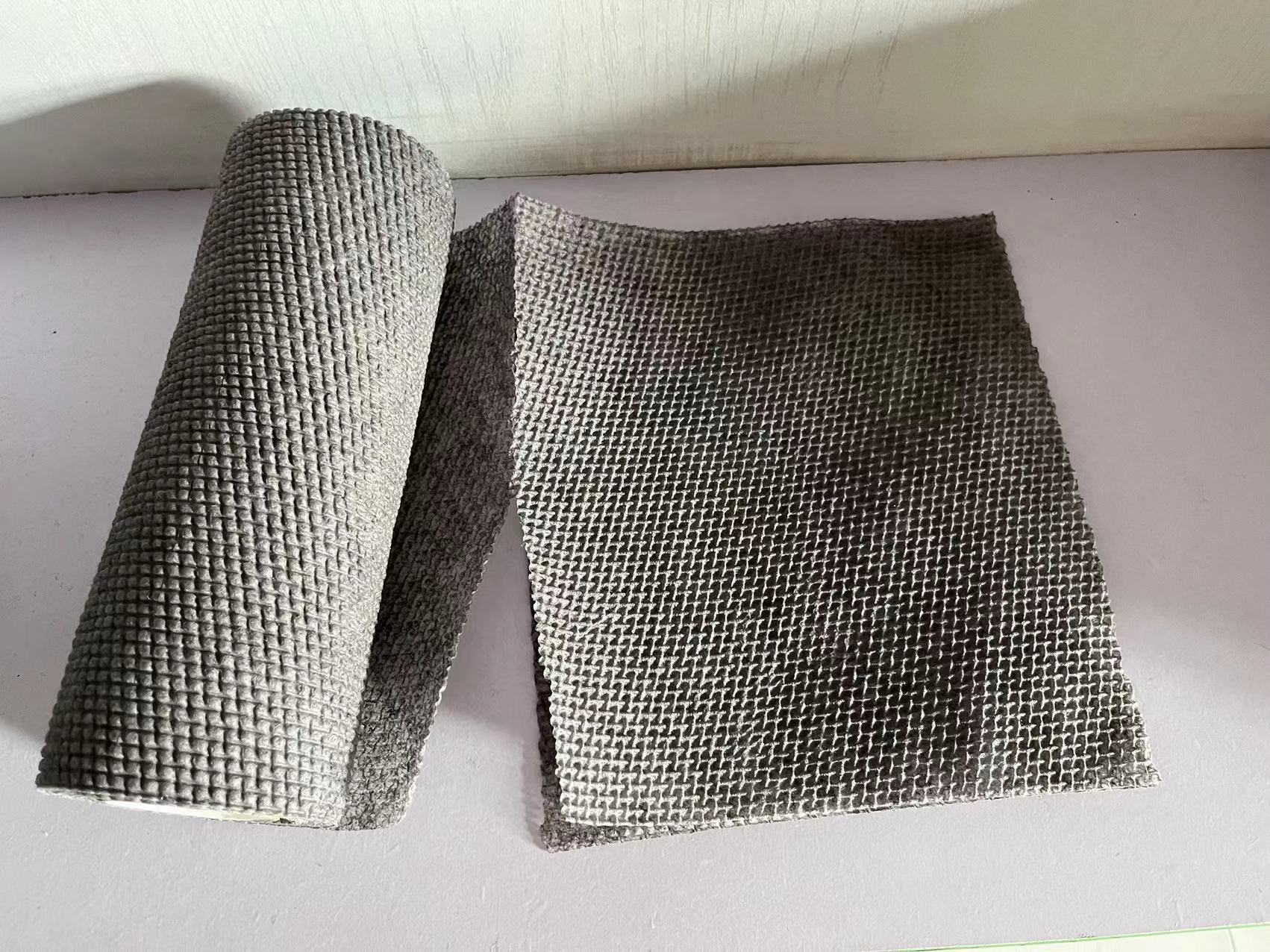

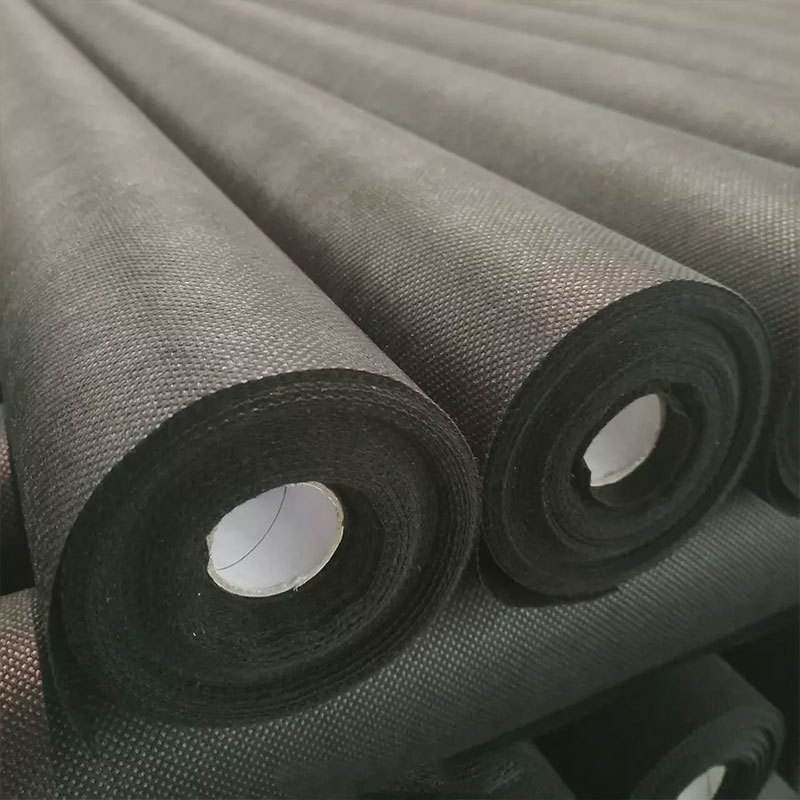

One of the most notable features of spunbond polypropylene fabric is its strength and durability. This fabric is created through a process where polypropylene fibers are spun and bonded together without the need for weaving or knitting. This unique manufacturing method confers high tensile strength, making it ideal for applications requiring robust materials. Moreover, its lightweight nature adds to its appeal, especially in industries where weight reduction is crucial.

Another key characteristic of spunbond polypropylene fabric is its excellent breathability and fluid resistance. These properties make it particularly suitable for medical and hygiene products, such as surgical gowns, face masks, and disposable bed linens. Additionally, the fabric’s ability to repel water while allowing air to circulate ensures comfort and hygiene—critical factors in healthcare settings.

The manufacturing process of spunbond polypropylene involves several steps, including polymer extrusion, fiber formation, and bonding. During polymer extrusion, polypropylene pellets are heated and melted to form a continuous filament. Subsequently, the filaments are drawn and laid out on a conveyor belt, where they are bonded using heat and pressure. This process results in a fabric that is not only strong but also versatile, as it can be produced in various thicknesses and widths to meet specific requirements.

Sustainability is an increasingly important consideration in the textile industry. Spunbond polypropylene fabric is recyclable, and advancements in production techniques have made it easier to reduce waste and energy consumption. Companies looking to implement environmentally friendly practices may find that incorporating recycled polypropylene into their products aligns with their sustainability goals.

Furthermore, the applications of spunbond polypropylene fabric extend beyond medical use. It is commonly employed in agriculture for crop protection, in construction for geotextiles, and even in fashion for innovative designs. Its adaptability makes it a valuable asset for various sectors, encouraging companies to explore new markets and applications.

In conclusion, understanding spunbond polypropylene fabric is essential for professionals in the nonwoven textile industry. Its unique characteristics, diverse applications, and sustainable aspects position it as a key material for current and future developments. By leveraging the properties of this fabric, businesses can enhance their product offerings and stay competitive in an evolving market.

One of the most notable features of spunbond polypropylene fabric is its strength and durability. This fabric is created through a process where polypropylene fibers are spun and bonded together without the need for weaving or knitting. This unique manufacturing method confers high tensile strength, making it ideal for applications requiring robust materials. Moreover, its lightweight nature adds to its appeal, especially in industries where weight reduction is crucial.

Another key characteristic of spunbond polypropylene fabric is its excellent breathability and fluid resistance. These properties make it particularly suitable for medical and hygiene products, such as surgical gowns, face masks, and disposable bed linens. Additionally, the fabric’s ability to repel water while allowing air to circulate ensures comfort and hygiene—critical factors in healthcare settings.

The manufacturing process of spunbond polypropylene involves several steps, including polymer extrusion, fiber formation, and bonding. During polymer extrusion, polypropylene pellets are heated and melted to form a continuous filament. Subsequently, the filaments are drawn and laid out on a conveyor belt, where they are bonded using heat and pressure. This process results in a fabric that is not only strong but also versatile, as it can be produced in various thicknesses and widths to meet specific requirements.

Sustainability is an increasingly important consideration in the textile industry. Spunbond polypropylene fabric is recyclable, and advancements in production techniques have made it easier to reduce waste and energy consumption. Companies looking to implement environmentally friendly practices may find that incorporating recycled polypropylene into their products aligns with their sustainability goals.

Furthermore, the applications of spunbond polypropylene fabric extend beyond medical use. It is commonly employed in agriculture for crop protection, in construction for geotextiles, and even in fashion for innovative designs. Its adaptability makes it a valuable asset for various sectors, encouraging companies to explore new markets and applications.

In conclusion, understanding spunbond polypropylene fabric is essential for professionals in the nonwoven textile industry. Its unique characteristics, diverse applications, and sustainable aspects position it as a key material for current and future developments. By leveraging the properties of this fabric, businesses can enhance their product offerings and stay competitive in an evolving market.

spunbond polypropylene fabric