12

2025

-

08

How Polyester Spunbond Nonwoven Fabric Can Improve Product Longevity

How Polyester Spunbond Nonwoven Fabric Can Improve Product Longevity Table of Contents 1. Introduction to Polyester Spunbond Nonwoven Fabric 2. What is Nonwoven Fabric? 3. Advantages of Spunbond Technology 4. How Polyester Nonwoven Fabric Enhances Product Longevity 5. Applications of Polyester Spunbond Nonwoven Fabric 6. Environmental Impact and Sustainability 7. Comparison with

How Polyester Spunbond Nonwoven Fabric Can Improve Product Longevity

Table of Contents

- 1. Introduction to Polyester Spunbond Nonwoven Fabric

- 2. What is Nonwoven Fabric?

- 3. Advantages of Spunbond Technology

- 4. How Polyester Nonwoven Fabric Enhances Product Longevity

- 5. Applications of Polyester Spunbond Nonwoven Fabric

- 6. Environmental Impact and Sustainability

- 7. Comparison with Other Fabric Types

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Polyester Spunbond Nonwoven Fabric

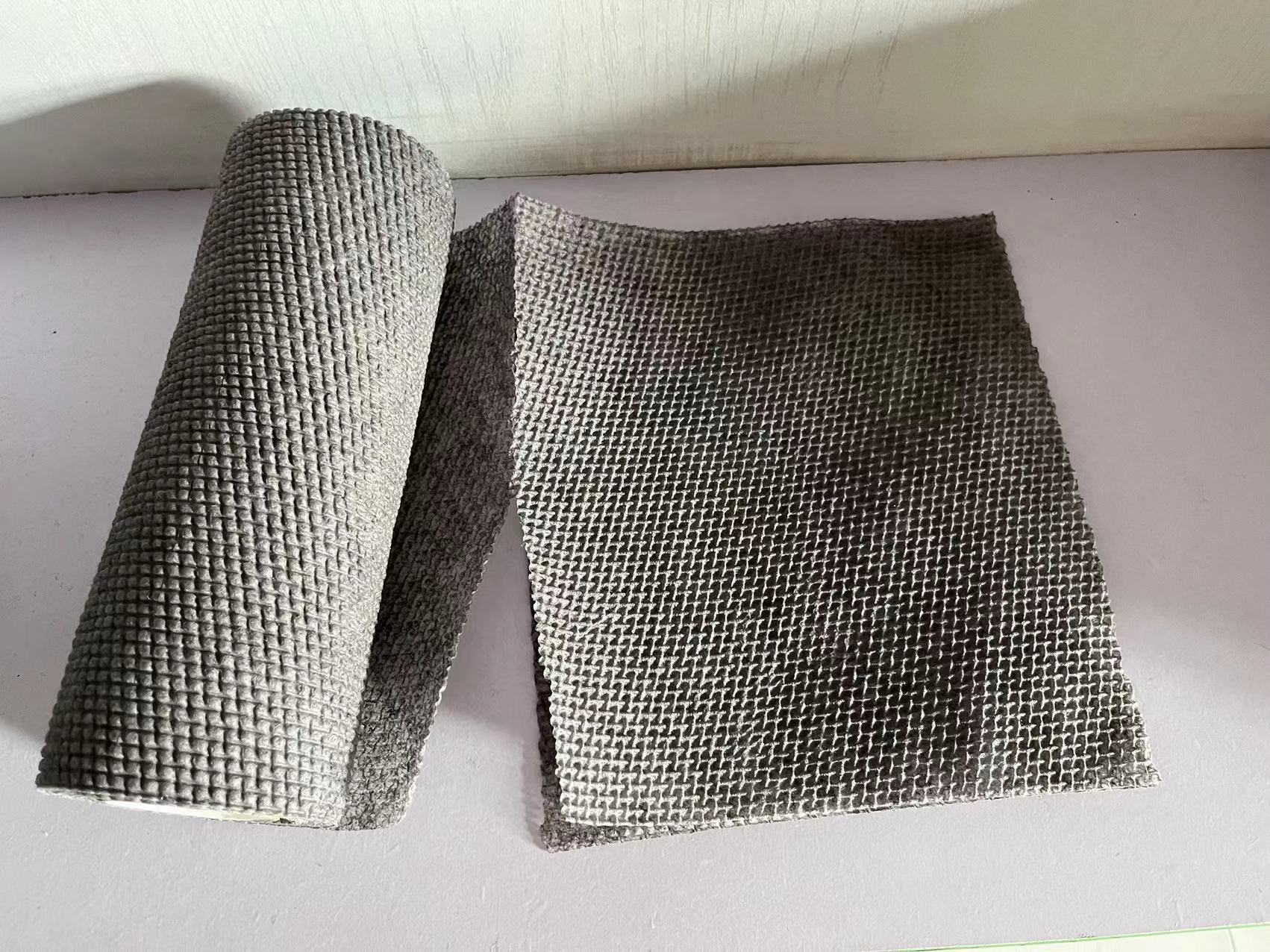

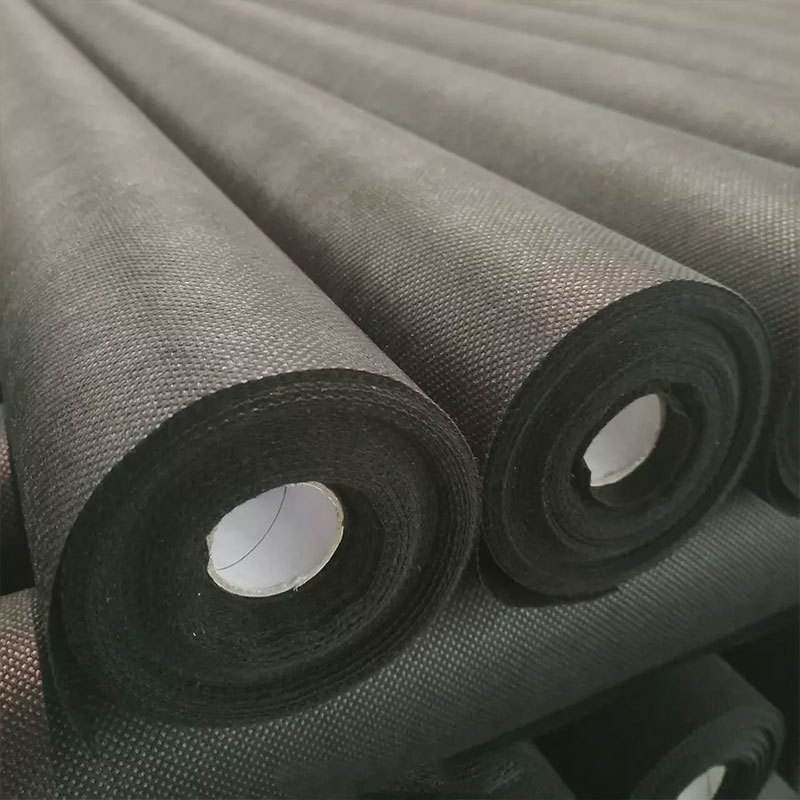

Polyester spunbond nonwoven fabric has revolutionized the textile industry by offering a unique combination of durability, versatility, and cost-effectiveness. This innovative material is produced through a process that involves bonding polyester fibers without weaving them, resulting in a fabric that is both light and strong. In this article, we will delve into how polyester spunbond nonwoven fabric enhances product longevity, making it an indispensable choice for various applications.

2. What is Nonwoven Fabric?

Nonwoven fabric is a type of textile that is created by mechanically, chemically, or thermally bonding fibers together, rather than through traditional weaving or knitting techniques. This process allows nonwoven fabrics to maintain their unique properties while being cost-effective and adaptable. Polyester spunbond, in particular, is made from continuous filament fibers that are laid out in a web and bonded together, creating a dense, strong material that is ideal for a variety of uses.

2.1 Characteristics of Nonwoven Fabric

Some of the distinguishing characteristics of nonwoven fabric include:

- **Lightweight**: Nonwoven fabrics are generally lighter than woven fabrics, making them ideal for applications where weight is a concern.

- **Breathability**: Many nonwoven fabrics allow air and moisture to pass through, providing comfort and reducing the risk of mold and mildew.

- **Durability**: The bonding process provides nonwoven fabrics with significant strength, enhancing their lifespan.

- **Versatility**: Nonwoven fabrics can be produced in various colors, textures, and thicknesses, making them suitable for myriad applications.

3. Advantages of Spunbond Technology

Spunbond technology offers several advantages that set it apart from other fabric manufacturing processes. The key benefits include:

3.1 Enhanced Strength

Spunbond nonwoven fabrics are known for their high tensile strength. The process of creating the fabric involves continuous filament fibers that are bonded together, resulting in a robust material that can withstand significant stress. This strength contributes to the longevity of products made from spunbond nonwoven fabric.

3.2 Cost-Effectiveness

The production of polyester spunbond nonwoven fabric is efficient and cost-effective. Because the manufacturing process can be automated, it requires less labor and time compared to traditional fabric production methods, making it an economical choice for manufacturers and consumers alike.

3.3 Customizability

Manufacturers can easily customize polyester spunbond nonwoven fabrics to meet specific requirements. This includes varying the thickness, texture, and color of the fabric, enabling a wide range of applications and enhancing marketability.

4. How Polyester Nonwoven Fabric Enhances Product Longevity

The longevity of products made from polyester spunbond nonwoven fabric can be attributed to several key factors:

4.1 Resistance to Wear and Tear

Products made from polyester spunbond nonwoven fabric exhibit exceptional resistance to wear and tear. This is crucial for applications where fabrics are subjected to friction or harsh conditions, such as in automotive interiors or agricultural covers.

4.2 Moisture Management

Polyester spunbond nonwoven fabric is known for its excellent moisture-wicking properties. This prevents the accumulation of moisture that could lead to mold, mildew, or degradation of the product, thereby prolonging its lifespan.

4.3 UV Resistance

The durability of polyester spunbond nonwoven fabric extends to its resistance to UV radiation. This feature is particularly important for outdoor applications where exposure to sunlight can cause fading and deterioration over time.

4.4 Chemical Resistance

Polyester spunbond nonwoven fabric can withstand exposure to a variety of chemicals without degrading. This characteristic is essential for industrial applications where fabrics may come into contact with harsh substances.

5. Applications of Polyester Spunbond Nonwoven Fabric

The versatility of polyester spunbond nonwoven fabric allows it to be used across numerous industries, including:

5.1 Medical and Healthcare

In the medical field, polyester spunbond nonwoven fabric is widely used for surgical gowns, masks, and drapes due to its barrier properties and comfort. The durability of the fabric ensures that these products maintain their integrity during use.

5.2 Agriculture

Agricultural applications include crop covers and greenhouse films, where the fabric's UV resistance and moisture management capabilities enhance plant health and yield.

5.3 Consumer Products

In consumer goods, polyester spunbond nonwoven fabric is found in items such as bags, disposable tableware, and filters, providing durability and aesthetic appeal.

5.4 Automotive

In the automotive industry, polyester spunbond nonwoven fabrics are used for interior linings, insulation, and sound dampening, contributing to both performance and comfort.

6. Environmental Impact and Sustainability

As environmental concerns continue to grow, the sustainability of materials is becoming increasingly important. Polyester spunbond nonwoven fabric can be produced from recycled materials, making it a more eco-friendly choice compared to traditional fabrics. Additionally, its long lifespan reduces waste, aligning with sustainable practices in manufacturing and consumption.

6.1 Biodegradability

While polyester does not break down as quickly as natural fibers, advancements in technology are leading to the development of biodegradable polyester nonwoven options that provide the benefits of traditional polyester while minimizing environmental impact.

7. Comparison with Other Fabric Types

To fully appreciate the advantages of polyester spunbond nonwoven fabric, it is essential to compare it with other fabric types:

7.1 Woven Fabrics

Woven fabrics are typically more rigid and less versatile than nonwoven options, making them less suitable for applications requiring flexibility and adaptability. Additionally, woven fabrics often experience fraying and unraveling, diminishing their lifespan.

7.2 Knitted Fabrics

While knitted fabrics offer stretch and comfort, they may lack the structural integrity and durability found in polyester spunbond nonwoven fabrics. This can result in a shorter lifespan for products made from knitted textiles.

7.3 Other Nonwoven Types

Other nonwoven types, such as needle-punched or thermal-bonded fabrics, may offer different properties. However, the unique combination of strength, weight, and flexibility provided by polyester spunbond nonwoven fabric often surpasses these alternatives in terms of product longevity.

8. Frequently Asked Questions

8.1 What is the difference between spunbond and other nonwoven processes?

Spunbond nonwoven fabric is created by extruding filaments, which are then laid out in a web and bonded together. This results in a fabric that is lightweight yet strong, compared to other nonwoven processes like needle-punching, which may result in denser but less flexible materials.

8.2 How does polyester spunbond nonwoven fabric fare against moisture?

Polyester spunbond nonwoven fabric excels in moisture management, allowing for breathability and preventing mold or mildew, thus enhancing product longevity.

8.3 Is it possible to recycle polyester spunbond nonwoven fabric?

Yes, polyester spunbond nonwoven fabric can be recycled, making it a more sustainable option in the textile industry.

8.4 What industries primarily use polyester spunbond nonwoven fabric?

Common industries utilizing this fabric include healthcare, agriculture, automotive, and consumer goods.

8.5 What factors contribute to the durability of polyester spunbond nonwoven fabric?

Factors include resistance to wear and tear, moisture management, UV resistance, and chemical resilience, all of which enhance product longevity.

9. Conclusion

Polyester spunbond nonwoven fabric offers unparalleled advantages in enhancing product longevity across a variety of applications. Its strength, durability, and resistance to environmental factors position it as a superior choice over traditional fabrics. As industries continue to embrace innovative materials, polyester spunbond nonwoven fabric is set to play a crucial role in shaping the future of textiles, ensuring products not only last longer but also meet the growing demand for sustainable solutions.

Polyester Spunbond Nonwoven Fabric