28

2025

-

08

Understanding the Production Process of Polyester Spunbond Fabric: A Comprehensive Guide

Understanding the Production Process of Polyester Spunbond Fabric Polyester spunbond fabric has revolutionized the textile industry with its unique properties and versatile applications. This comprehensive guide explores the intricate production process of polyester spunbond fabric, its various uses, and what makes it a sought-after material in countless industries. Table of Contents What is

Understanding the Production Process of Polyester Spunbond Fabric

Polyester spunbond fabric has revolutionized the textile industry with its unique properties and versatile applications. This comprehensive guide explores the intricate production process of polyester spunbond fabric, its various uses, and what makes it a sought-after material in countless industries.

Table of Contents

- What is Polyester Spunbond Fabric?

- The Importance of Polyester in Textiles

- Overview of the Production Process

- Step 1: Polymerization

- Step 2: Spinning

- Step 3: Web Formation

- Step 4: Bonding

- Step 5: Finishing

- Applications of Polyester Spunbond Fabric

- Advantages and Disadvantages of Polyester Spunbond Fabric

- Frequently Asked Questions

- Conclusion

What is Polyester Spunbond Fabric?

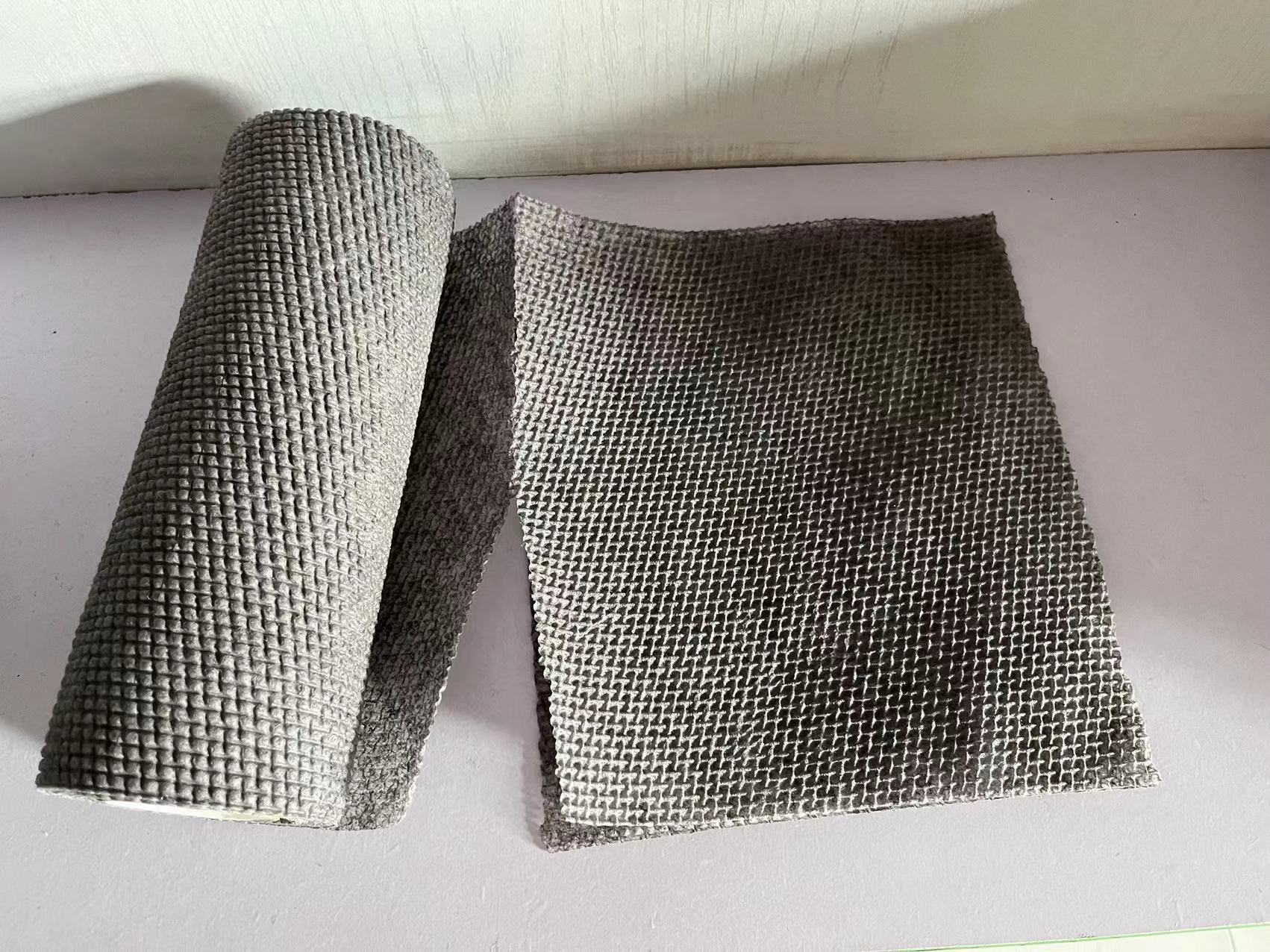

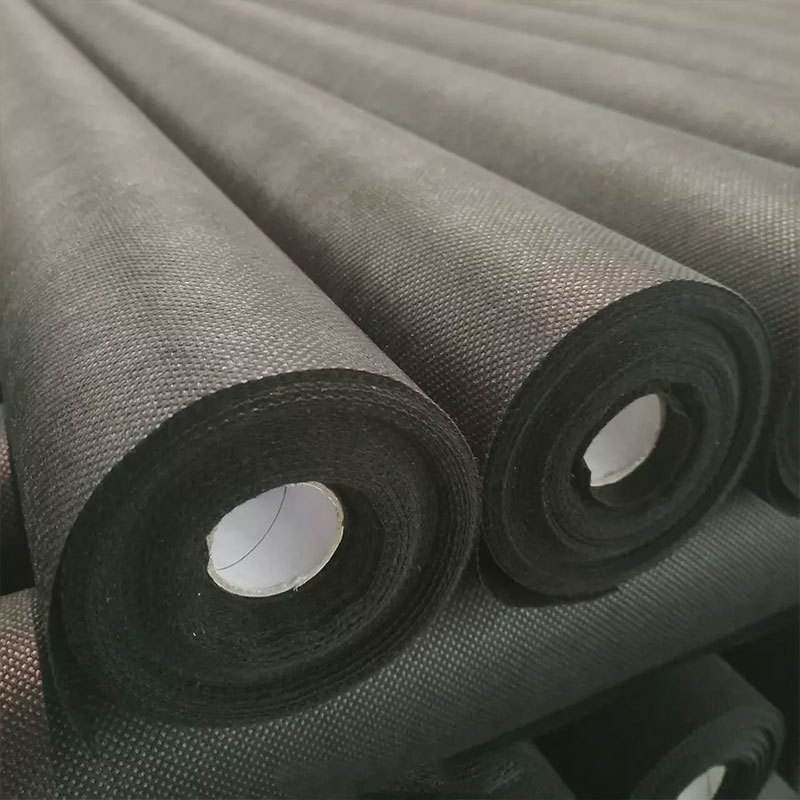

Polyester spunbond fabric is a nonwoven textile made from polyester fibers. This innovative fabric is produced using a unique spunbond process that allows for the creation of a durable, lightweight, and versatile material. Unlike traditional woven fabrics, spunbond fabrics do not require any weaving process, making them more efficient to produce and more affordable for various applications.

The Importance of Polyester in Textiles

Polyester has gained immense popularity in the textile industry due to its exceptional strength, durability, and resistance to wrinkles and shrinking. These qualities make polyester an ideal choice for various applications, from clothing to industrial uses. The spunbonding process further enhances these properties, resulting in a fabric that is not only reliable but also cost-effective.

Overview of the Production Process

The production of polyester spunbond fabric involves several critical steps. Each stage plays a vital role in ensuring the final product meets industry standards for quality and performance. The key steps include polymerization, spinning, web formation, bonding, and finishing.

Step 1: Polymerization

The first step in the production of polyester spunbond fabric is polymerization. This process involves chemically synthesizing polyester from its raw materials, typically derived from petroleum. The most common method of polymerization used in the production of polyester is the condensation polymerization method. In this step, ethylene glycol and terephthalic acid undergo a reaction to form long chains of polyester.

The quality of polyester produced during this stage is crucial, as it directly impacts the properties of the final spunbond fabric. Factors such as molecular weight, degree of crystallinity, and viscosity are carefully monitored to ensure that the polyester meets the required specifications for spunbonding.

Step 2: Spinning

Once the polyester is synthesized, the next step is spinning. In this phase, the polyester is heated and melted before being extruded through a spinneret—a device that contains numerous tiny holes. As the molten polyester exits the spinneret, it cools and solidifies into continuous filaments.

These filaments can vary in diameter, allowing manufacturers to control the fabric's density and texture. The spinning process is critical, as it determines the strength and uniformity of the individual fibers that will be used to form the spunbond fabric.

Step 3: Web Formation

After spinning, the next step is web formation. In this stage, the continuous filaments are laid down onto a conveyor system to form a web structure. Various methods can be employed for this process, including air-laying, carding, or using a cross-lapper to achieve the desired web structure.

The web formation process not only influences the final fabric's appearance but also its mechanical properties. The fibers can be arranged in different patterns, allowing for customization based on the intended application.

Step 4: Bonding

Bonding is a crucial stage in the production of polyester spunbond fabric, as it determines the integrity and strength of the final product. There are several methods of bonding, including thermal bonding, chemical bonding, and ultrasonic bonding.

In thermal bonding, the web of fibers is passed through heated rollers, causing the fibers to partially melt and fuse together. This method is widely used due to its efficiency and the strength it provides to the final fabric. Chemical bonding, on the other hand, involves applying a bonding agent that adheres the fibers together, resulting in a different fabric feel and flexibility.

Step 5: Finishing

The final step in the production process is finishing, where additional treatments are applied to enhance the fabric's properties. This can include processes such as dyeing, printing, and applying coatings for water resistance or fire retardancy.

Finishing treatments not only improve the aesthetic qualities of the fabric but also its functional characteristics, making polyester spunbond fabric suitable for a wide range of applications.

Applications of Polyester Spunbond Fabric

Polyester spunbond fabric is utilized across various industries due to its inherent properties. Some common applications include:

- **Medical and Hygiene Products**: Used in disposable gowns, masks, and diapers, polyester spunbond fabric is valued for its barrier properties and comfort.

- **Agricultural Uses**: The fabric is used for row covers and mulch films, providing protection for crops while allowing light and moisture to penetrate.

- **Automotive Industry**: Polyester spunbond fabric is used for interior car linings, sound insulation, and in the manufacturing of airbags.

- **Home Furnishings**: This fabric is found in upholstery, curtains, and other home textile products due to its durability and versatility.

- **Construction**: Used as a vapor barrier and in roofing applications, polyester spunbond fabric provides essential protection and insulation.

Advantages and Disadvantages of Polyester Spunbond Fabric

**Advantages**:

1. **Durability**: Polyester spunbond fabric is exceptionally strong and resistant to wear and tear.

2. **Lightweight**: The fabric is lightweight, making it easy to handle and transport.

3. **Cost-effective**: The production process is efficient, leading to lower costs compared to traditional woven fabrics.

4. **Versatile**: It can be tailored for a range of applications across different industries.

5. **Eco-friendly options**: Recycled polyester can be used, contributing to sustainability efforts.

**Disadvantages**:

1. **Breathability**: While durable, spunbond fabric may not be as breathable as woven alternatives.

2. **Heat Sensitivity**: Polyester can be sensitive to high temperatures, which may limit its uses in certain applications.

3. **Limited stretchability**: Unlike some woven fabrics, polyester spunbond lacks elastic properties, which may restrict its use in specific applications.

Frequently Asked Questions

**1. What is polyester spunbond fabric made of?**

Polyester spunbond fabric is made from polyester fibers that are melted and extruded to form continuous filaments, which are then bonded together to create a nonwoven textile.

**2. What are the benefits of using polyester spunbond fabric?**

The benefits include durability, lightweight construction, cost-effectiveness, and a wide range of applications in various industries.

**3. How is polyester spunbond fabric different from traditional woven fabric?**

Unlike woven fabrics, which are made by interlacing yarns, spunbond fabric is produced by bonding together synthetic fibers, resulting in a fabric that is often stronger and more versatile.

**4. Can polyester spunbond fabric be recycled?**

Yes, polyester spunbond fabric can be made from recycled polyester, contributing to environmental sustainability and reducing waste.

**5. What industries commonly use polyester spunbond fabric?**

Common industries include medical and hygiene, agriculture, automotive, home furnishings, and construction.

Conclusion

The production process of polyester spunbond fabric is a sophisticated and intricate procedure that yields a unique and versatile material. With its remarkable properties and diverse applications, polyester spunbond fabric continues to make a significant impact across various industries. Understanding the various stages of production not only highlights the fabric's importance but also emphasizes its potential for innovation in the textile landscape. As we continue to explore the capabilities of polyester spunbond fabric, it is clear that it will remain a vital player in shaping the future of textiles.

polyester spunbond fabric