17

2025

-

12

Understanding Spunbond Polypropylene Fabric: A Versatile Solution in Nonwoven Textiles

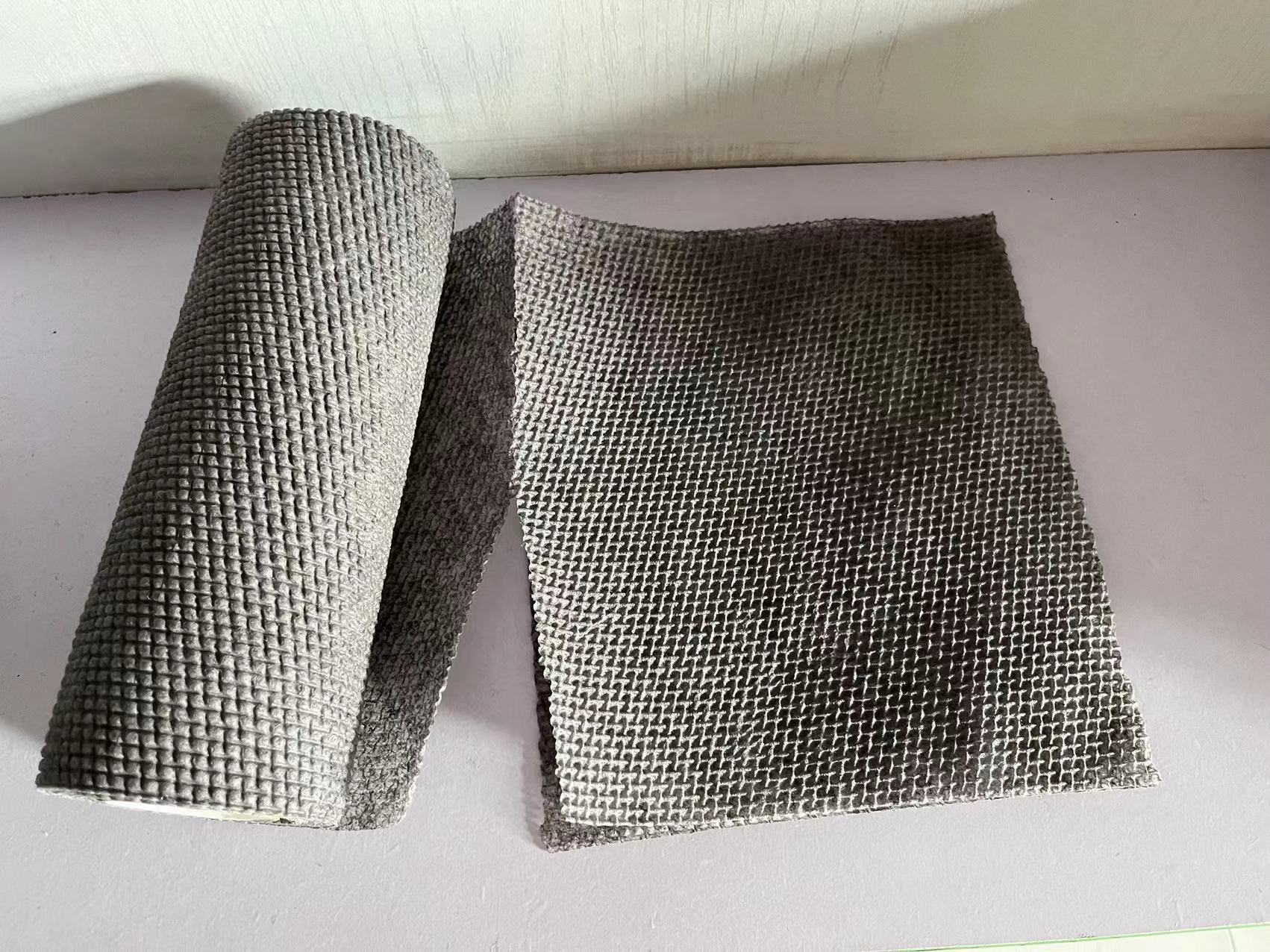

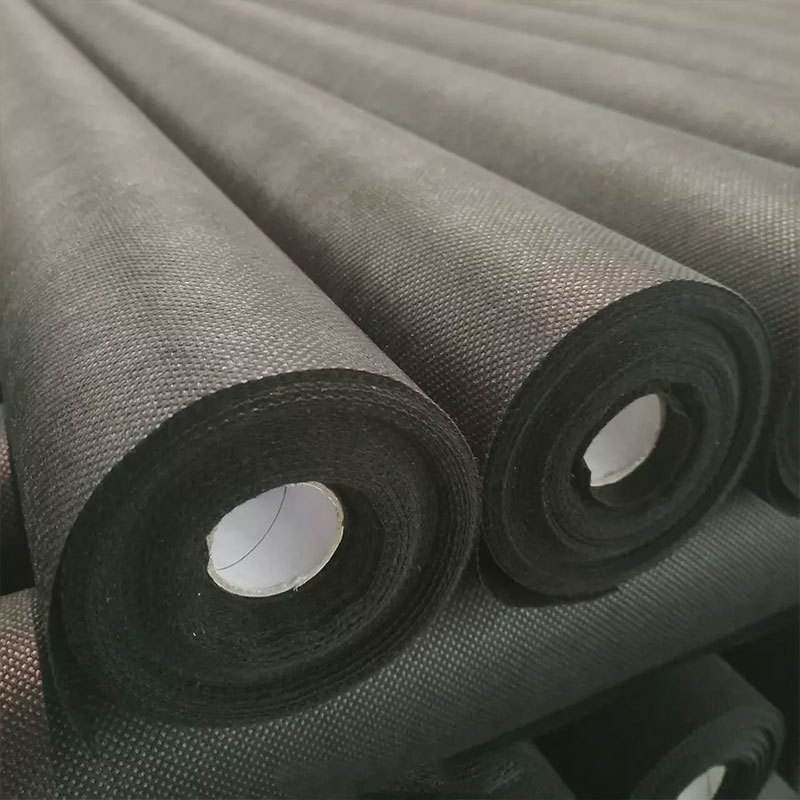

Spunbond polypropylene fabric, a type of nonwoven material, offers a combination of durability, lightweight characteristics, and versatility, making it a popular choice across various industries. This fabric is produced through a process that involves the extrusion of molten polypropylene, followed by the spinning of long filaments which are laid randomly and bonded together through heat and press

Spunbond polypropylene fabric, a type of nonwoven material, offers a combination of durability, lightweight characteristics, and versatility, making it a popular choice across various industries. This fabric is produced through a process that involves the extrusion of molten polypropylene, followed by the spinning of long filaments which are laid randomly and bonded together through heat and pressure. The result is a robust fabric that boasts numerous benefits.

One of the standout features of spunbond polypropylene fabric is its excellent strength-to-weight ratio. This property makes it particularly useful in applications where lightweight materials are required without compromising on strength. In addition, the fabric exhibits remarkable tear resistance and is highly capable of withstanding mechanical stresses, making it suitable for both industrial and consumer products.

Another significant advantage of spunbond polypropylene fabric is its resistance to moisture and chemicals. This characteristic is especially beneficial in applications such as agricultural covers, where the fabric can protect crops from the elements while allowing essential air and moisture exchange. Furthermore, its chemical resistance makes it ideal for use in environments where exposure to various substances is a concern, such as in hospitals and laboratories.

The versatility of spunbond polypropylene fabric extends to its ability to be easily dyed and printed, allowing for a wide range of aesthetic options. This makes it a favored choice in the fashion industry for accessories and bags, as well as in promotional materials. Additionally, its lightweight nature allows for easier handling and transportation, which is an attractive quality for manufacturers and distributors alike.

In terms of sustainability, spunbond polypropylene fabric can be produced with recycled materials and is recyclable itself, aligning with the growing demand for eco-friendly options in the textile market. This aspect not only helps reduce environmental impact but also provides manufacturers with opportunities to market their products as sustainable solutions.

Moreover, spunbond polypropylene fabric can be engineered to meet specific properties, such as UV resistance or antimicrobial treatments, further expanding its application range. Its use is prevalent in personal protective equipment (PPE), medical gowns, and masks, where protection and comfort are paramount.

In conclusion, spunbond polypropylene fabric stands out in the nonwoven textiles sector due to its unique combination of strength, versatility, and eco-friendliness. Whether used in healthcare, agriculture, fashion, or industrial applications, this fabric continues to play a vital role in meeting the diverse needs of various industries. Understanding its properties and potential uses can help professionals make informed decisions when selecting materials for their projects.

One of the standout features of spunbond polypropylene fabric is its excellent strength-to-weight ratio. This property makes it particularly useful in applications where lightweight materials are required without compromising on strength. In addition, the fabric exhibits remarkable tear resistance and is highly capable of withstanding mechanical stresses, making it suitable for both industrial and consumer products.

Another significant advantage of spunbond polypropylene fabric is its resistance to moisture and chemicals. This characteristic is especially beneficial in applications such as agricultural covers, where the fabric can protect crops from the elements while allowing essential air and moisture exchange. Furthermore, its chemical resistance makes it ideal for use in environments where exposure to various substances is a concern, such as in hospitals and laboratories.

The versatility of spunbond polypropylene fabric extends to its ability to be easily dyed and printed, allowing for a wide range of aesthetic options. This makes it a favored choice in the fashion industry for accessories and bags, as well as in promotional materials. Additionally, its lightweight nature allows for easier handling and transportation, which is an attractive quality for manufacturers and distributors alike.

In terms of sustainability, spunbond polypropylene fabric can be produced with recycled materials and is recyclable itself, aligning with the growing demand for eco-friendly options in the textile market. This aspect not only helps reduce environmental impact but also provides manufacturers with opportunities to market their products as sustainable solutions.

Moreover, spunbond polypropylene fabric can be engineered to meet specific properties, such as UV resistance or antimicrobial treatments, further expanding its application range. Its use is prevalent in personal protective equipment (PPE), medical gowns, and masks, where protection and comfort are paramount.

In conclusion, spunbond polypropylene fabric stands out in the nonwoven textiles sector due to its unique combination of strength, versatility, and eco-friendliness. Whether used in healthcare, agriculture, fashion, or industrial applications, this fabric continues to play a vital role in meeting the diverse needs of various industries. Understanding its properties and potential uses can help professionals make informed decisions when selecting materials for their projects.

spunbond polypropylene fabric

Prev