11

2026

-

01

Understanding PP Spunbond Nonwoven Fabric: Characteristics and Applications

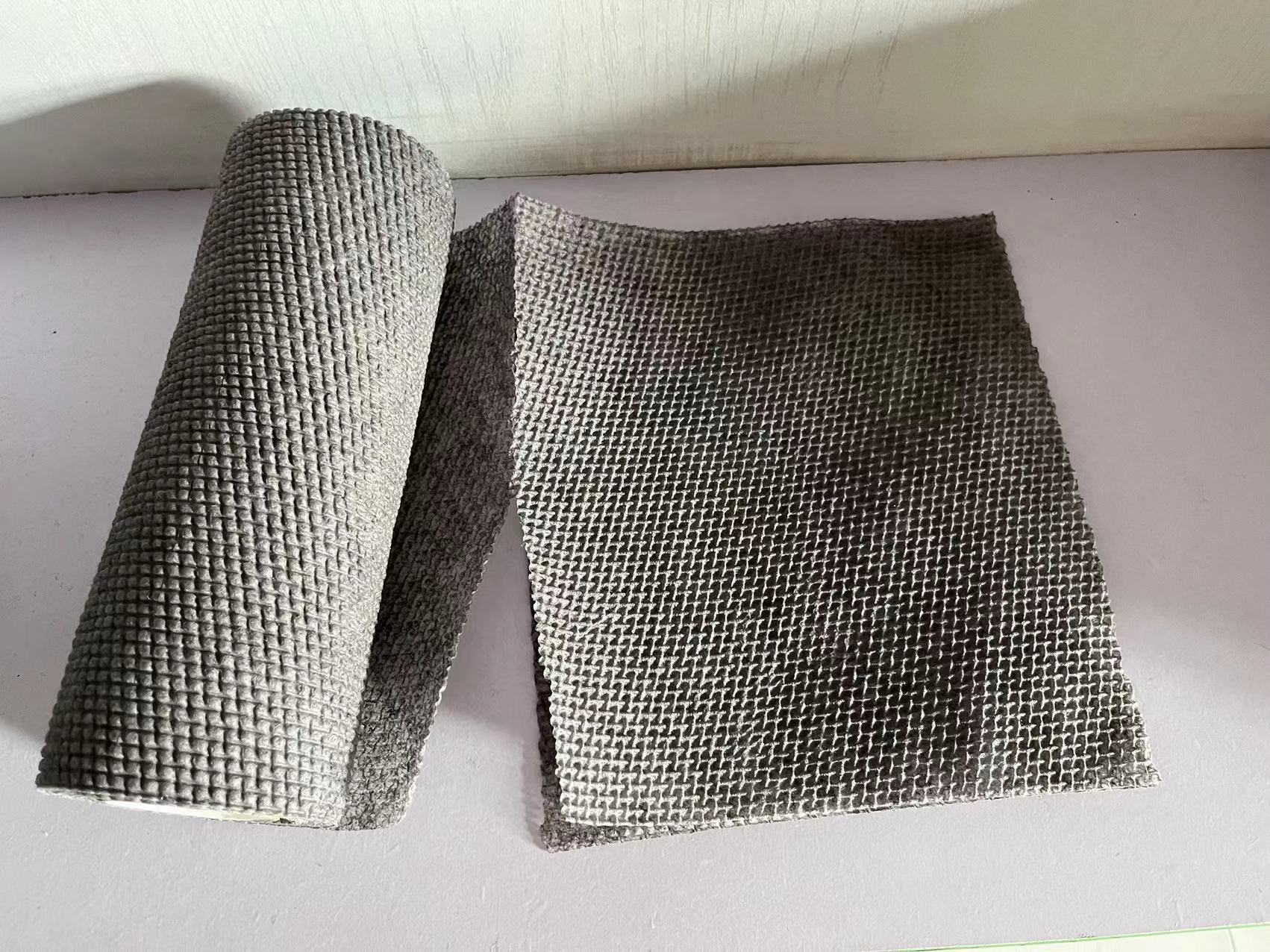

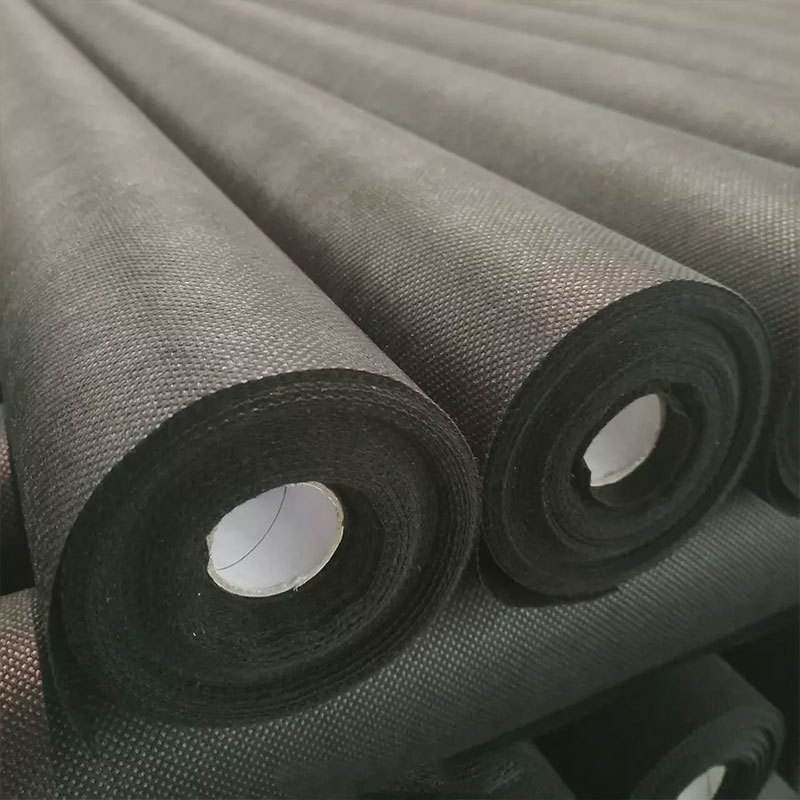

PP spunbond nonwoven fabric is a revolutionary material in the textile industry, particularly within the nonwoven fabric sector. Made from polypropylene (PP), this fabric is produced through a spunbonding process that involves melting polypropylene pellets and extruding them into continuous filaments. These filaments are then laid down and bonded together, creating a strong and durable fabric that

PP spunbond nonwoven fabric is a revolutionary material in the textile industry, particularly within the nonwoven fabric sector. Made from polypropylene (PP), this fabric is produced through a spunbonding process that involves melting polypropylene pellets and extruding them into continuous filaments. These filaments are then laid down and bonded together, creating a strong and durable fabric that is lightweight and versatile.

One of the primary characteristics of PP spunbond nonwoven fabric is its exceptional strength. The unique structure provides high tensile strength, making it suitable for various applications where durability is essential. Additionally, this fabric exhibits excellent resistance to tearing, making it a reliable choice for products that may be subjected to stress or strain during use.

Another significant feature of PP spunbond nonwoven fabric is its breathability. The fabric's unique structure allows for air and moisture to pass through, making it ideal for applications such as medical and hygiene products, where ventilation is crucial. This breathability also contributes to the comfort of end-users, particularly in products like surgical gowns, face masks, and disposable bedding.

In terms of environmental impact, PP spunbond nonwoven fabric is noteworthy. It is recyclable and can be produced with eco-friendly practices, making it an increasingly popular choice for environmentally conscious consumers and manufacturers. Furthermore, the absence of chemical binders in its production process enhances its appeal for use in sensitive applications, such as baby products and medical textiles.

PP spunbond nonwoven fabric is widely used across various industries. In the medical field, its properties make it an ideal choice for surgical drapes, masks, and gowns. In the hygiene sector, it is commonly found in products like diapers and feminine hygiene items. The automotive industry also utilizes this fabric for interior components and insulation, while the agriculture sector employs it for crop protection and landscaping.

The adaptability of PP spunbond nonwoven fabric further extends to apparel, where it can be used in the production of lightweight clothing and accessories. Its ability to be dyed and printed upon allows designers to create visually appealing products while maintaining the fabric’s inherent qualities.

In summary, PP spunbond nonwoven fabric stands out for its strength, breathability, eco-friendliness, and versatility. Its applications are broad, spanning medical, hygiene, automotive, agricultural, and apparel sectors. As industries continue to seek innovative materials that meet both performance and environmental standards, PP spunbond nonwoven fabric remains a leading choice in the textile landscape. Understanding its characteristics and applications can help businesses make informed decisions in their product development and manufacturing processes.

One of the primary characteristics of PP spunbond nonwoven fabric is its exceptional strength. The unique structure provides high tensile strength, making it suitable for various applications where durability is essential. Additionally, this fabric exhibits excellent resistance to tearing, making it a reliable choice for products that may be subjected to stress or strain during use.

Another significant feature of PP spunbond nonwoven fabric is its breathability. The fabric's unique structure allows for air and moisture to pass through, making it ideal for applications such as medical and hygiene products, where ventilation is crucial. This breathability also contributes to the comfort of end-users, particularly in products like surgical gowns, face masks, and disposable bedding.

In terms of environmental impact, PP spunbond nonwoven fabric is noteworthy. It is recyclable and can be produced with eco-friendly practices, making it an increasingly popular choice for environmentally conscious consumers and manufacturers. Furthermore, the absence of chemical binders in its production process enhances its appeal for use in sensitive applications, such as baby products and medical textiles.

PP spunbond nonwoven fabric is widely used across various industries. In the medical field, its properties make it an ideal choice for surgical drapes, masks, and gowns. In the hygiene sector, it is commonly found in products like diapers and feminine hygiene items. The automotive industry also utilizes this fabric for interior components and insulation, while the agriculture sector employs it for crop protection and landscaping.

The adaptability of PP spunbond nonwoven fabric further extends to apparel, where it can be used in the production of lightweight clothing and accessories. Its ability to be dyed and printed upon allows designers to create visually appealing products while maintaining the fabric’s inherent qualities.

In summary, PP spunbond nonwoven fabric stands out for its strength, breathability, eco-friendliness, and versatility. Its applications are broad, spanning medical, hygiene, automotive, agricultural, and apparel sectors. As industries continue to seek innovative materials that meet both performance and environmental standards, PP spunbond nonwoven fabric remains a leading choice in the textile landscape. Understanding its characteristics and applications can help businesses make informed decisions in their product development and manufacturing processes.

pp spunbond nonwoven fabric