12

2026

-

01

Polyester Spunbond Nonwoven Fabric in Filtration: A Comprehensive Guide to Its Applications and Benefits

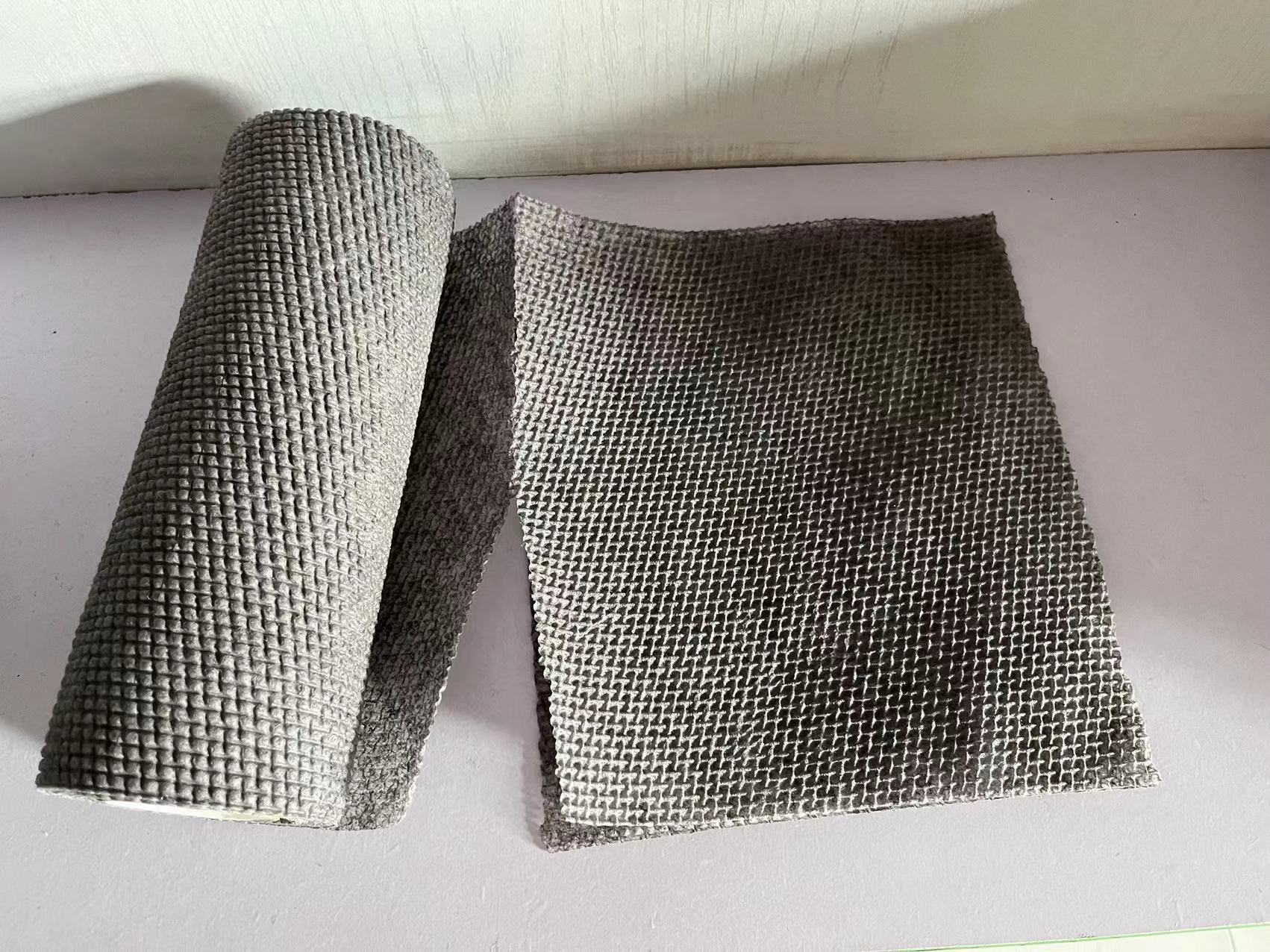

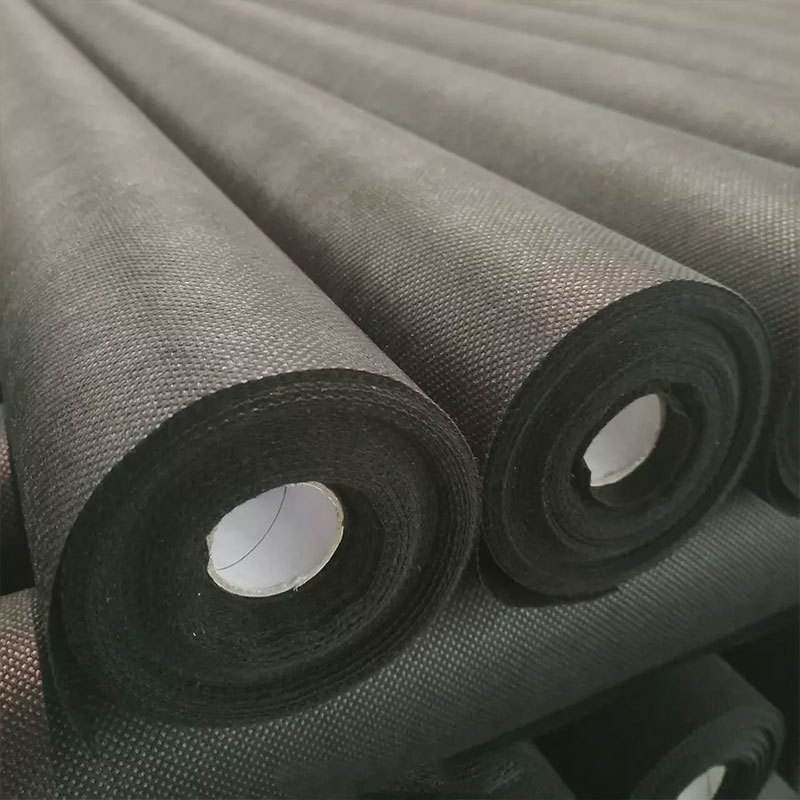

Polyester Spunbond Nonwoven Fabric in Filtration: What You Need to Know Introduction to Polyester Spunbond Nonwoven Fabric Polyester spunbond nonwoven fabric is a unique textile material formed by bonding together polyester fibers through a spinning process. This type of fabric is characterized by its high strength, durability, and versatility, making it a popular choice across various industries,

Polyester Spunbond Nonwoven Fabric in Filtration: What You Need to Know

Introduction to Polyester Spunbond Nonwoven Fabric

Polyester spunbond nonwoven fabric is a unique textile material formed by bonding together polyester fibers through a spinning process. This type of fabric is characterized by its high strength, durability, and versatility, making it a popular choice across various industries, especially in filtration applications. In this article, we will explore the properties, applications, and advantages of polyester spunbond nonwoven fabric in filtration systems.

Understanding the Basics: What is Nonwoven Fabric?

Nonwoven fabric differs significantly from traditional woven or knitted fabrics. Instead of interlacing threads, nonwovens are made from fibers that are bonded together using mechanical, thermal, or chemical processes. This manufacturing method results in a fabric that offers unique features, such as:

- **Lightweight and Flexible**: Nonwovens are often lighter than their woven counterparts, allowing for easy handling and installation in various applications.

- **High Filtration Efficiency**: The structure of nonwoven fabrics enables them to capture particles effectively, making them ideal for filtration systems.

- **Cost-Effectiveness**: Nonwoven fabrics, including polyester spunbond, are generally more affordable due to lower production costs and material usage.

Key Properties of Polyester Spunbond Nonwoven Fabrics

The performance of polyester spunbond nonwoven fabrics in filtration applications is attributed to their specific properties:

1. Chemical Resistance

Polyester fibers are inherently resistant to a range of chemicals, allowing them to maintain structural integrity in harsh environments. This property is particularly beneficial in filtration systems that encounter various chemicals and pollutants.

2. High Tensile Strength

The spunbond process creates a fabric with outstanding tensile strength, enabling it to withstand high pressure and mechanical stress without tearing or deforming. This durability is crucial in applications where the filter media is subject to constant flow and pressure changes.

3. Thermal Stability

Polyester spunbond nonwoven fabric exhibits excellent thermal stability, allowing it to perform effectively in high-temperature environments. This makes it suitable for applications where the filtration process generates heat, such as industrial exhaust systems.

Applications of Polyester Spunbond Nonwoven Fabric in Filtration

Polyester spunbond nonwoven fabric is widely used in various filtration applications. Its versatility and effectiveness make it a preferred material for numerous industries, including:

1. Air Filtration Systems

In air filtration, polyester spunbond nonwoven fabric is commonly used in HVAC systems, air purifiers, and industrial air filters. Its ability to trap airborne particles, such as dust, pollen, and smoke, helps improve indoor air quality and protect individuals from respiratory issues.

2. Liquid Filtration

Polyester spunbond nonwoven fabric is also employed in liquid filtration applications, such as water treatment plants and beverage filtration. Its fine fibers effectively capture contaminants, ensuring the purity of the final product.

3. Automotive Filtration

In the automotive industry, polyester spunbond nonwoven fabric is used in cabin air filters and engine air intake systems. It plays a vital role in preventing harmful particles from entering the vehicle, contributing to a cleaner and safer driving experience.

4. Medical Filtration

The medical sector utilizes polyester spunbond nonwoven fabric in various filtration applications, including surgical masks, gowns, and sterile packaging. Its biocompatibility and filtration efficiency help maintain hygiene standards and protect healthcare workers and patients alike.

Advantages of Polyester Spunbond Nonwoven Fabric in Filtration

Choosing polyester spunbond nonwoven fabric for filtration applications offers several distinct advantages over traditional filtration materials:

1. Enhanced Filtration Efficiency

The unique structure of polyester spunbond nonwoven fabric allows for high filtration efficiency, capturing a greater percentage of particles compared to traditional woven options. This characteristic is crucial in applications where air and water purity is paramount.

2. Lightweight and Easy to Handle

The lightweight nature of polyester spunbond nonwoven fabric simplifies transportation and installation, making it a favored choice among manufacturers and end-users. This feature can lead to lower shipping costs and reduced labor expenses during installation.

3. Customizable Properties

Polyester spunbond nonwoven fabric can be engineered to meet specific filtration requirements. By adjusting fiber density, thickness, and other manufacturing parameters, it is possible to create a product tailored for unique applications.

Environmental Impact of Polyester Spunbond Nonwoven Fabric

Given the increased focus on sustainability and environmental protection, the use of polyester spunbond nonwoven fabric raises important considerations:

1. Recyclability and Sustainability

Polyester is a recyclable material, and initiatives are underway to develop recycling processes for nonwoven fabrics. By investing in recycling technologies, the industry can minimize waste and contribute to a circular economy.

2. Reducing Environmental Footprint

By enhancing filtration efficiency, polyester spunbond nonwoven fabrics can help reduce emissions and waste, leading to a lower overall environmental impact. Their use in air and water filtration systems contributes to cleaner ecosystems.

Future Trends in Polyester Spunbond Nonwoven Fabric for Filtration

As technology continues to advance, the future of polyester spunbond nonwoven fabric in filtration applications looks promising:

1. Innovations in Fabric Technology

Research and development efforts are focused on enhancing the filtration properties of polyester spunbond nonwoven fabrics. Innovations may include electrospinning techniques, nanofiber integration, and advanced bonding methods that further improve filtration efficiency.

2. Growing Demand in Various Industries

The demand for high-performance filtration materials is expected to increase across multiple sectors, including automotive, healthcare, and environmental management. Polyester spunbond nonwoven fabric will likely play a pivotal role in meeting these growing needs.

Frequently Asked Questions (FAQs)

1. What is the difference between spunbond and meltblown nonwoven fabrics?

Spunbond nonwoven fabrics are made by continuously extruding molten polymer and bonding the fibers together, while meltblown nonwoven fabrics are produced by blowing molten polymer fibers through a nozzle. Meltblown fabrics typically have finer fibers and higher filtration efficiency but may not be as durable as spunbond fabrics.

2. How effective is polyester spunbond nonwoven fabric in capturing airborne particles?

Polyester spunbond nonwoven fabric is highly effective in capturing airborne particles, achieving high filtration efficiency due to its unique fiber structure that traps dust, pollen, and other pollutants.

3. Can polyester spunbond nonwoven fabric be reused or recycled?

While polyester itself is a recyclable material, the recyclability of nonwoven fabrics depends on specific recycling processes. Some manufacturers are exploring methods to recycle used nonwoven materials.

4. In which industries is polyester spunbond nonwoven fabric most commonly used?

Polyester spunbond nonwoven fabric is widely used in air and liquid filtration, automotive, medical, and industrial applications, among others.

5. What are the maintenance requirements for polyester spunbond nonwoven filters?

Maintenance requirements vary depending on the application, but generally, polyester spunbond nonwoven filters should be inspected regularly, and replacement schedules should be followed to ensure optimal filtration performance.

Conclusion

Polyester spunbond nonwoven fabric has emerged as a vital material in the filtration industry, thanks to its unique properties, diverse applications, and numerous advantages over traditional filtration materials. As we look to the future, ongoing innovations and a growing emphasis on sustainability will further enhance its role in creating cleaner air and water. Understanding the significance of polyester spunbond nonwoven fabric in filtration systems equips manufacturers, businesses, and consumers with the knowledge to make informed choices for a healthier environment.

Polyester Spunbond Nonwoven Fabric